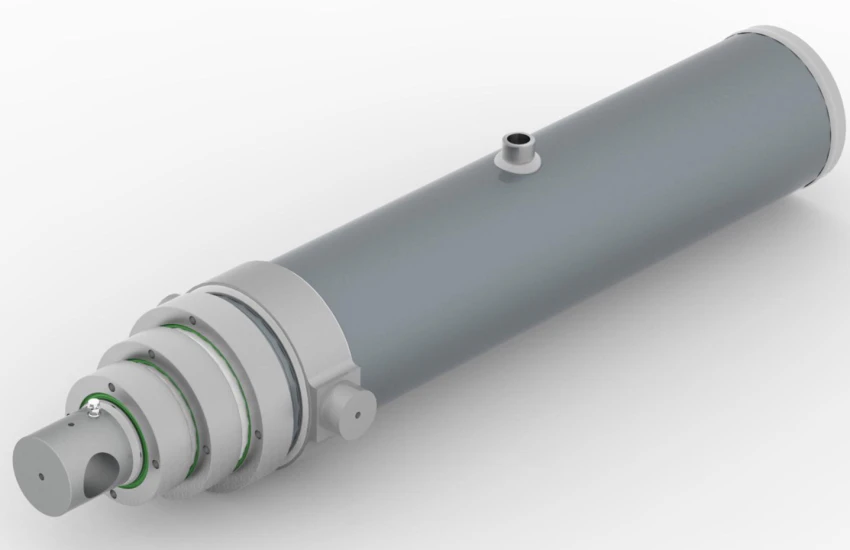

Telescopic Cylinders

Leading Manufacturer and Supplier of High-Performance Telescopic Cylinders

Our company is a leading manufacturer and distributor specializing in telescopic cylinders. With years of expertise in the industry, we pride ourselves on offering a diverse range of telescopic cylinders designed to meet our clients' varying needs. Our telescopic cylinders are renowned for their exceptional performance, durability, and precision, making them ideal for various applications across various industries.

At our company, we prioritize innovation and quality. We are constantly engaged in research and development to ensure that our telescopic cylinders remain at the forefront of technological advancements. Our team of experts is dedicated to providing exceptional customer service, ensuring that our clients receive the best possible support and solutions.

We are committed to building long-term relationships with our customers and partners, striving to exceed their expectations with every product we sell. Whether you're looking for a telescopic cylinder for industrial use or a specific application, our company is here to provide you with the best possible solution.

Advantages of Telescopic Cylinders over Traditional Hydraulic Cylinders

| Feature | Telescopic Cylinders | Traditional Hydraulic Cylinders |

|---|---|---|

| Stroke Length | Offer significantly longer stroke lengths for the same closed length, thanks to their multi-stage design. | Limited stroke length relative to the cylinder's overall size. |

| Space Efficiency | Highly compact when retracted, making them ideal for applications with limited space. | Require more space for the same stroke length due to their single-stage design. |

| Weight | Can be lighter than traditional cylinders when offering the same stroke, due to the overlapping sections. | Generally heavier for equivalent stroke capabilities, affecting overall system weight. |

| Versatility | Can be designed for a wide range of applications requiring long extensions and compact retraction. | Best suited for applications where space is not a constraint and shorter strokes are adequate. |

| Installation | The compact retracted size allows for easier installation in tight spaces. | May require more complex installations due to their larger size for equivalent strokes. |

| Cost-Effectiveness | In some applications, the ability to achieve longer strokes without the need for additional mechanical systems can be more cost-effective. | May require additional mechanical systems to achieve the desired motion, increasing costs. |

| Load Capacity | The design allows for high load capacities even with extended strokes, making them suitable for lifting heavy loads. | Load capacity can decrease with longer strokes due to bending moments and buckling risks. |

| Maintenance | Maintenance can be more complex due to the multiple stages and seals involved. | Generally simpler to maintain due to their straightforward design. |

| Customization | High degree of customization possible to meet specific application requirements. | Less flexibility in customization due to the constraints of single-stage design. |

| Speed of Operation | The extension and retraction speeds can be controlled and varied between stages. | Extension and retraction speeds are consistent but may not be as easily customizable. |

What is a telescopic cylinder?

Telescopic cylinder is a common hydraulic component widely used in industrial production and mechanical equipment. It uses the hydraulic principle to realize the telescopic function through the pressure of liquid. The working principle of the telescopic cylinder is based on the principle of hydraulic force transmission. When external pressure is applied, liquid will enter the cylinder barrel of the cylinder. As the liquid enters, the piston will move outward under the action of pressure, thereby achieving the elongation effect. . When the external pressure decreases or disappears, the liquid will prevent backflow through the action of valves or seals, thereby maintaining the state of the telescopic cylinder.

Telescopic cylinders can be divided into 2, 3, 4, and 5-stage telescopic cylinders according to the number of telescopic stages; according to the number of liquid supplies to complete a working cycle, they can be divided into single-acting and double-acting multi-stage hydraulic cylinders, among which single-acting The multi-stage cylinder is a plunger telescopic hydraulic cylinder, and the double-acting multi-stage hydraulic cylinder is a piston telescopic hydraulic cylinder. In addition, there is also a telescopic hydraulic cylinder with a piston as the final stage and a plunger as the front multi-stage or first stage.

Wide range of industrial applications for telescopic cylinders

Construction Industry: Used in various construction machinery and equipment, such as concrete pump trucks, cranes, and tower cranes, to improve construction efficiency and safety.

Agriculture: Used on agricultural machinery and equipment, such as tractor front-end loaders, harvesters, and sprayers, to improve operational efficiency and adaptability.

Mining and Resource Extraction: In mining and resource extraction, equipment, such as mining trucks and excavators, handles heavy loads and harsh environments.

Transportation & Logistics: Used in dump trucks, trailers, and other transportation equipment to facilitate the quick and efficient loading and unloading of cargo.

Manufacturing: Used in automated production lines and robotic arms for precise control and improved production efficiency.

Sanitation industry: used in sanitation equipment such as garbage trucks and sweepers to facilitate the collection and treatment of waste.

Emergency Rescue & Safety: Used in fire trucks and rescue equipment for rescue and fire extinguishing operations.

Marine Engineering is used on offshore platforms, ships, and diving equipment to perform specific offshore operations and research tasks.

Municipal Engineering and Maintenance: Used in vehicle maintenance, street light maintenance, and sewer cleaning equipment to ensure the regular operation of urban infrastructure.

Energy Industry: It is used to regulate and control energy production equipment in wind power generation and oil and gas extraction.

Characteristics of telescopic cylinder

Compact Retracted Length

When fully retracted, the telescopic cylinder is much shorter than its fully extended length, making it particularly ideal in space-constrained applications.

Efficient force output

Although the telescopic cylinder can provide a long stroke when fully extended, it is still designed to ensure strong force output, suitable for applications requiring large forces and long strokes.

Variable stroke length

The telescopic cylinder can extend a different number of segments as needed, thus providing a variety of stroke lengths and increasing flexibility of use.

FAQ

What are the different types or variations of telescopic cylinders?

1. Single-acting telescopic cylinder: This type of cylinder can only perform telescopic movement in one direction. Its main features are simple structure, small size, and stable performance.

2. Double-acting telescopic cylinder: Unlike single-acting telescopic cylinders, double-acting telescopic cylinders have the capability of bidirectional telescopic movement. Its structure is similar to a single-acting telescopic cylinder, but it needs to be connected to hydraulic sources in both directions.

3. Multi-stage telescopic cylinder: This type of cylinder has two or multi-stage pistons. The order of the piston extension is from large to small, while the order of no-load retraction is generally from small to large. The telescopic cylinder can achieve a longer stroke but has a shorter length when retracted, making the structure more compact. This kind of cylinder is often used in construction machinery and agricultural machinery.

What key factors need to be considered during the design process of telescopic cylinders?

1. Load and thrust: This is the first factor to consider when designing a telescopic cylinder. According to the actual application requirements, determine the maximum load and thrust of the cylinder, which will directly determine the diameter of the selected cylinder and the strength of the material.

2. Hydraulic system: The hydraulic system is the core of controlling the movement of the telescopic cylinder. The design process requires selecting an appropriate system to provide the required hydraulic oil pressure and flow. Typically, a hydraulic pump provides hydraulic oil, while a hydraulic valve controls the flow direction and pressure of the oil.

3. Piston Materials and Seals: The selection of piston materials and seals is critical to properly operating the telescopic cylinder. The piston material needs to be stiff and corrosion-resistant. Common piston materials include steel, aluminum, and copper. The seals need good performance and wear resistance to ensure the cylinder does not leak under high-pressure and high-speed working environments.

4. Structure and size: The structure and size of the telescopic cylinder are also essential considerations in the design process. According to the application requirements and the space conditions of the mechanical equipment, determine the structural form (such as single-acting or double-acting) and cylinder size. In addition, the safety margin should also be considered during design to ensure the stability and safety of the cylinder in actual work.

5. Control system design: The control system design of the telescopic cylinder is also an essential part. The control system needs to perform well and respond to signals accurately and quickly to achieve precise cylinder movement.

6. Experimental verification and optimization: After the design is completed, a series of experimental verification and optimization work is required. This includes load testing, sealing performance testing, durability testing, etc., to ensure that the telescopic cylinder's performance meets the requirements. The design is adjusted and improved based on the experimental results to achieve the desired effect.

What should we pay attention to during the installation process of telescopic cylinder?

1. Cleaning and preparation: Before installation, the installation surface should be clean to prevent impurities from entering the cylinder and affecting its work. At the same time, the required installation tools and materials should be prepared.

2. Installation direction: Connect according to the instructions in the telescopic cylinder's manual. Pay attention to the cylinder's direction to ensure correct installation.

3. Fixing and connection: Firmly fix the telescopic cylinder's fixed point and ensure that the connection between it and the installation equipment is firm and reliable. During the installation process, care should be taken not to damage the piston rod by knocking, friction, etc.

4. Oil port protection: During the installation process, if the oil port of the oil cylinder has not yet been installed with a joint, the oil port blocking component should not be removed to prevent foreign matter from entering the cylinder.

5. Parallelism of the mounting surface: During installation, ensure the parallelism of the mounting surface, and lock the screws diagonally when tightening the screws to ensure the stability of the installation.

6. Rod head connection: After installation, do not lock the fixed part of the rod head connection during assembly. Pre-tighten it first. After the cylinder has been actuated 3 to 5 times, tighten the screws to ensure the concentricity and parallelism of the fit.

7. Safety precautions: During the installation process, operating procedures must be followed to avoid safety accidents caused by improper operation. Personnel should stay away from the movement range of the oil cylinder to avoid accidents.

Materials and technologies used in the manufacturing process of telescopic cylinders

Get The Obedient Dog Of Your Dreams!

First of all, regarding materials, the main components of telescopic cylinders such as cylinder block, piston rod, sealing structure, etc. are usually made of high-quality steel. As the main load-bearing part of the telescopic cylinder, the cylinder body needs to use high-strength, high-wear-resistant steel to ensure that it can withstand high pressure and frequent telescopic movements. The piston rod is required to have good rigidity and corrosion resistance to ensure its stability and durability during work. In addition, the materials used in the sealing structure also need to have excellent sealing performance and wear resistance to ensure that the cylinder does not leak in a high-pressure environment.

During the manufacturing process, the technologies involved include precision machining, heat treatment, surface treatment, etc. Precision machining technology is used to ensure the dimensional accuracy and surface quality of cylinders, piston rods and other components to meet sealing and movement performance requirements. Heat treatment technology is used to improve the mechanical properties and process performance of the material, and increase the load-bearing capacity and service life of the telescopic cylinder. Surface treatment technologies such as spraying, plating, etc. are used to enhance the corrosion resistance and wear resistance of components and improve the overall performance of the cylinder.

Why choose our company?

1. High-quality products: Our company is committed to providing the highest quality hydraulic cylinders. Our products are precision engineered and manufactured using advanced materials to ensure durability, reliability and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising on quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know that a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement and maintenance, ensuring that your hydraulic cylinders are in optimal condition for a longer period of time.

5. Rich product range: Our company provides a variety of hydraulic cylinder to meet different applications and requirements. We can provide you with the right product.