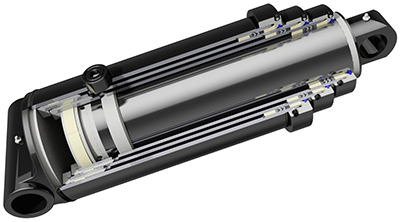

Product Description

Specifications:

| Product Name | HSG Series Hydraulic Cylinder |

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

| Bore Size | 40mm--320mm, Customizable |

| Shaft Diameter | 20mm--220mm, Customizable |

| Stroke Length | 30mm--14100mm, Customizable |

| Rod Surface Hardness | HRC48-54 |

| Operating Temperature | -40°C to +120 °C |

| Paint Color | Black, Yellow, Blue, Brown, Customizable |

| Service | OEM&ODM |

| Warranty | 1 Year |

| MOQ | 1 Piece |

| Delivery Time | 7-15 Days, Also depending on specific demands |

| Certification | ISO9001,CE |

| Capacity | 50,000Pcs per year |

Product Display:

Mounting:

Working Flow: About Us

Tongte designs and manufactures durable, heavy-duty hydraulic products and accessories and offers lifecycle services to them. We constantly develop our machine base and operations to meet customer-specific needs and remain leaders in the industry. Beyond all else, we want to be the trusted, groundbreaking partner our customers truly need.

In addition to the customized cylinders, CHINAMFG offers hydraulic power units, Electric-Hydraulic linear actuators, piston accumulators, system configurations, and versatile services such as repair and manufacturing services. The modern production facilities are located in HangZhou, ZheJiang (China) where production started in 2001. The core values of Tongke guiding its business strongly are commitment, sustainability, interaction, and customer-first.

We possess over 20 years of experience in the industry and extensive global market experience, our customers are located all over the world, and we truly commit to the customers' needs - these are the success factors of our family-owned company. Our vision is to grow and expand the business further into global markets.

FAQ:

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinders, Hydraulic Power packs, Hydraulic Linear, and other Hydraulic components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3:Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, and 15-30 working days if we don't. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What is your warranty policy?

A: All our products are warranted for 1 full year from the date of delivery against defects in materials and workmanship. Each individual product will be strictly inspected on our factory QC Process

System before shipment. We also have a Customer Service team to respond to customers' questions within 12 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do telescopic cylinders handle variations in environmental conditions?

Telescopic cylinders are designed to handle variations in environmental conditions effectively. Here's a detailed explanation:

Durable construction:

Telescopic cylinders are constructed with durable materials such as steel or high-strength alloys, which provide resistance to environmental elements. These materials are chosen for their ability to withstand harsh conditions, including temperature extremes, moisture, and exposure to chemicals or corrosive substances.

Sealing mechanisms:

Telescopic cylinders incorporate sealing mechanisms to protect the internal components from contaminants and maintain proper operation in different environments. The seals prevent the entry of dust, dirt, water, and other particles that could potentially damage the cylinder's internal components or affect its performance. Seals also help retain the hydraulic fluid, ensuring optimal lubrication and preventing leakage.

Corrosion resistance:

Telescopic cylinders are often coated with protective finishes or treatments to enhance their corrosion resistance. These coatings, such as paint, powder coating, or specialized coatings like chrome plating, create a barrier between the cylinder's surface and the surrounding environment, reducing the risk of corrosion. Corrosion-resistant materials and treatments are particularly crucial in outdoor or marine applications where exposure to moisture, saltwater, or chemicals is common.

Temperature considerations:

Telescopic cylinders are designed to handle variations in temperature. The materials used in their construction are selected to withstand both low and high temperature ranges. Additionally, the hydraulic fluid used in the cylinders is chosen based on its ability to maintain consistent performance across different temperature conditions. In extreme temperature environments, additional insulation or heating elements may be incorporated to ensure proper fluid viscosity and prevent freezing or overheating.

Environmental sealing:

In certain applications where telescopic cylinders are exposed to extreme environmental conditions, additional sealing measures may be implemented. Environmental seals are designed to provide extra protection against water, dust, or other contaminants that are prevalent in specific environments. These seals are typically more robust and durable to maintain the integrity of the cylinder in challenging conditions.

Regular maintenance:

To ensure optimal performance and longevity, regular maintenance is essential for telescopic cylinders. This includes inspecting and cleaning the cylinders, checking and replacing worn seals, monitoring fluid levels and quality, and addressing any signs of damage or wear. Maintenance intervals may vary depending on the operating conditions and manufacturer recommendations.

Overall, telescopic cylinders are engineered to handle variations in environmental conditions by incorporating durable construction, sealing mechanisms, corrosion resistance, temperature considerations, environmental sealing, and regular maintenance. These features contribute to the reliability, longevity, and performance of telescopic cylinders in diverse industrial applications.

Consulting with manufacturers or industry experts can provide further guidance on selecting telescopic cylinders that are suitable for specific environmental conditions.

How do telescopic cylinders handle variations in hydraulic seal technology?

Telescopic cylinders are designed to accommodate variations in hydraulic seal technology. Here's a detailed explanation:

Compatibility with different seal types:

Telescopic cylinders are engineered to be compatible with various types of hydraulic seals available in the market. Whether it's a standard O-ring seal, lip seal, V-ring seal, or any other seal design, the cylinder's construction takes into account the requirements of different seal technologies. This compatibility ensures that telescopic cylinders can effectively handle variations in hydraulic seal technology.

Seal retention and protection:

Telescopic cylinders incorporate features to retain and protect hydraulic seals. The cylinder design includes seal grooves, seal retainers, or other mechanisms that securely hold the seals in place, preventing their displacement or damage during operation. This seal retention and protection mechanism ensures the longevity and effectiveness of the seals, regardless of the specific seal technology used.

Seal lubrication and contamination prevention:

Telescopic cylinders address the lubrication and contamination concerns associated with different seal technologies. The cylinder's hydraulic system is designed to provide proper lubrication to the seals, ensuring smooth movement and reducing friction. Additionally, measures such as seal scrapers or wipers are implemented to prevent the ingress of contaminants, such as dust, dirt, or moisture, which could compromise the performance of the seals. These lubrication and contamination prevention mechanisms cater to the specific requirements of various seal technologies.

Seal replacement and maintenance:

Telescopic cylinders are designed to facilitate seal replacement and maintenance procedures. The cylinder construction allows for easy access to the seals, simplifying the replacement process when necessary. This feature is advantageous when dealing with different seal technologies, as it enables swift and efficient maintenance, regardless of the specific seal design being used.

Adaptability to seal advancements:

Telescopic cylinder designs often incorporate adaptability to advancements in hydraulic seal technology. Manufacturers continuously develop new seal technologies to improve performance, durability, and efficiency. Telescopic cylinders are designed with flexibility to accommodate future advancements, ensuring compatibility with emerging seal technologies and allowing for upgrade possibilities without significant modifications to the cylinder itself.

Overall, telescopic cylinders are engineered to handle variations in hydraulic seal technology through compatibility with different seal types, seal retention and protection features, seal lubrication and contamination prevention mechanisms, ease of seal replacement and maintenance, and adaptability to seal advancements. These design considerations ensure that telescopic cylinders can effectively work with different seal technologies, providing reliable and efficient performance in hydraulic systems.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the recommended seal types and maintenance practices for telescopic cylinders.

Can you explain the purpose and role of telescopic cylinders in machinery?

Telescopic cylinders play a crucial role in various machinery and equipment applications. Here's a detailed explanation:

Purpose of telescopic cylinders:

Telescopic cylinders are primarily used when an extended stroke length is required while maintaining a compact retracted length. They enable machinery and equipment to achieve extended reach, height adjustment, or lifting capabilities without increasing the overall size or footprint of the cylinder. The purpose of telescopic cylinders is to provide efficient and reliable linear motion in applications that demand long stroke lengths.

Role of telescopic cylinders in machinery:

- Material Handling: Telescopic cylinders are extensively used in material handling machinery, such as cranes, forklifts, and loaders. They enable the extension and retraction of booms, arms, or lifting mechanisms, allowing operators to reach higher or farther to handle and transport materials with ease.

- Dump Trucks and Trailers: Telescopic cylinders are commonly employed in dump trucks and trailers for the tilting and unloading of cargo or bulk materials. The extendable stroke of the cylinder raises the bed or container to dump the contents, enabling efficient unloading and reducing manual labor.

- Aerial Platforms: Telescopic cylinders are essential components in aerial work platforms, such as cherry pickers or scissor lifts. They facilitate the vertical movement and height adjustment of the platform, allowing operators to access elevated work areas safely.

- Construction Equipment: Telescopic cylinders are used in various construction equipment, including excavators, backhoes, and telescopic handlers. They provide the necessary extension and retraction for the boom, arm, or bucket, enabling digging, lifting, and reaching capabilities in construction and earthmoving applications.

- Mobile Equipment: Telescopic cylinders are utilized in mobile equipment, such as telescopic cranes and mobile cranes. They enable the extension and retraction of the boom sections, allowing for increased reach and lifting capacities in lifting and construction operations.

- Specialized Machinery: Telescopic cylinders find application in specialized machinery, such as fire truck aerial ladders, telescopic masts, or telescopic booms in industrial and military equipment. They provide the required extension and retraction for specific tasks, such as firefighting, surveillance, or equipment deployment.

The role of telescopic cylinders in machinery is to provide precise and controlled linear motion, enabling the equipment to perform specific tasks with extended reach, height adjustment, or lifting capabilities. They contribute to the efficiency, versatility, and productivity of machinery in various industries.

It's important to ensure proper selection, installation, and maintenance of telescopic cylinders based on the specific machinery requirements and manufacturer's guidelines to ensure safe and reliable operation.

editor by Dream 2024-04-26