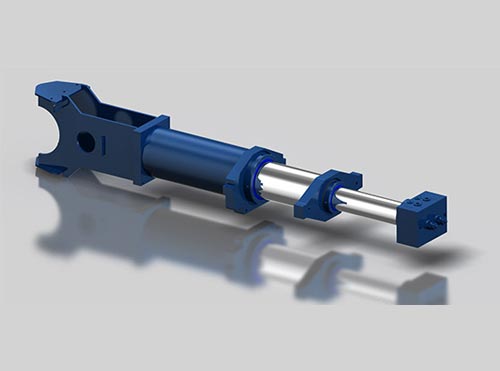

Product Description

Product Advantage:

1. Safer Junfu hydraulic cylinder adopts excellent structural design and new material application, which can withstand the harshest working conditions and continue to work stably without disconnection, ensuring the safety of drivers and vehicles, and creating the most valuable safety for users.

2. faster unloading

Junfu series oil cylinder adopts excellent structural design to improve the unloading speed of the oil cylinder!

3.higher lift frequency

junfu series oil cylinders are suitable for all-weather short barge and high-frequency operations, with stable performance, extremely low failure rate, increasing the number of transfers and reducing downtime!

4. Greater adaptability to the environment

junfu series oil cylinder adopts innovative sealing technology and new material application, which can adapt to the temperature range of -40~110ºC, and can achieve excellent performance in high temperature and low temperature environment operation!

5. lighter

Compared with other products of the same series, CHINAMFG series cylinders reduce the dead weight by 15%~20%, and increase the lifting force by 10%~15%!

6. Greater lifting force

Compared with other products of the same series, the lifting force of CHINAMFG series cylinders is increased by 10%~15%. More lift, more load, more profit! Lighter dead weight, greater lifting force, more lightness!

Enterprise Certificate

Our partner

Our Service

FAQ:

Q1: How about the quality?

Our cylinders can replace HYVA cylinder well, with same technical details and mounting sizes

Q2: What's your cylinder's advantages ?

The cylinders are manufactured by advanced equipments and made under strictly quality control processing.

The steel is tempered and all raw materials are good quality from world famous companies.

Competitive price!

Q3: When your company be established ?

Our company be established in 2002, professional manufacturer of hydraulic cylinders more than 20 years.

We had passed IATF 16949:2016 Quality control system, ISO9001, CE.

Q4: How about the delivery time ?

15 days approximately.

Q5: How about the cylinder's quality gurantee ?

One year.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CE, ISO9001, SGS |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 800/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can telescopic cylinders be repaired or maintained when necessary?

Yes, telescopic cylinders can be repaired and maintained when necessary. Here's a detailed explanation:

Repairability:

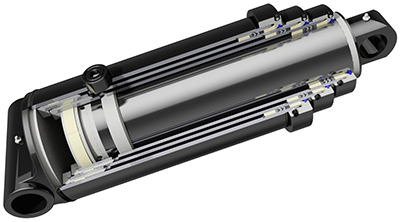

Telescopic cylinders are designed with repairability in mind. The modular construction of telescopic cylinders allows for individual components or stages to be replaced or repaired as needed. If a specific part of the cylinder becomes damaged or worn out, it can be disassembled and repaired or replaced, minimizing downtime and cost compared to replacing the entire cylinder.

Maintenance:

Maintenance is essential to ensure the optimal performance and longevity of telescopic cylinders. Regular maintenance practices may include:

- Inspection: Periodic visual inspections to check for any signs of damage, wear, or leakage.

- Lubrication: Applying lubricants to the moving parts of the cylinder to reduce friction and extend component life.

- Cleaning: Removing dirt, debris, and contaminants that may affect the cylinder's operation.

- Seal replacement: Replacing worn or damaged seals to maintain proper sealing and prevent fluid leakage.

- Pressure testing: Conducting pressure tests to ensure the cylinder's integrity and identify any potential issues.

- Alignment and adjustment: Verifying proper alignment and making necessary adjustments to ensure smooth operation and prevent excessive wear.

Depending on the specific application and operating conditions, maintenance intervals and procedures may vary. It's important to follow the manufacturer's maintenance recommendations and guidelines for the telescopic cylinder to ensure effective maintenance practices.

Professional expertise:

Repairing and maintaining telescopic cylinders often require professional expertise. It is recommended to engage qualified technicians or service personnel with experience in hydraulic systems and telescopic cylinder repairs. They have the knowledge and tools necessary to accurately diagnose issues, perform repairs, and conduct maintenance tasks in a safe and efficient manner.

Manufacturer support:

Manufacturers of telescopic cylinders typically provide support for repair and maintenance. They may offer technical documentation, repair manuals, and access to replacement parts to facilitate the repair process. Consulting the manufacturer's resources and seeking their assistance can ensure that repairs and maintenance are carried out correctly and in accordance with the cylinder's specifications.

By implementing proper repair and maintenance practices, telescopic cylinders can be kept in good working condition, extending their service life and maintaining reliable performance.

It's important to note that repair and maintenance should be performed by qualified individuals and comply with relevant safety guidelines and industry standards.

Can telescopic cylinders be used in manufacturing machinery for material processing?

Yes, telescopic cylinders are commonly used in manufacturing machinery for material processing tasks. Here's a detailed explanation:

Material handling and manipulation:

Telescopic cylinders are utilized in manufacturing machinery to handle and manipulate materials during the processing stages. They enable lifting, lowering, pushing, or pulling of components, parts, or raw materials, facilitating various manufacturing operations such as cutting, bending, shaping, or assembly.

Positioning and alignment:

Telescopic cylinders contribute to precise positioning and alignment of materials in manufacturing machinery. The controlled extension and retraction of the cylinders allow operators to align workpieces accurately, ensuring consistent quality, dimensional accuracy, and proper fit during material processing.

Adjustable working height:

In manufacturing machinery, telescopic cylinders provide the advantage of adjustable working height. By extending or retracting the cylinders, the height of the work surface or processing area can be modified to accommodate different material sizes or operator preferences. This flexibility enhances ergonomics and facilitates efficient material processing.

Modular design for customization:

Telescopic cylinders feature a modular design that allows for customization according to specific manufacturing requirements. The number of stages or sections can be adjusted to achieve the desired extended length and capacity of the cylinder. This modularity enables telescopic cylinders to be tailored to the dimensions and processing needs of different manufacturing machinery.

Force generation and control:

Telescopic cylinders generate the necessary force to perform material processing tasks. The hydraulic control system regulates the extension and retraction of the cylinders, allowing operators to control the force applied during cutting, bending, or other processing operations. This force control ensures precise and consistent material processing while minimizing the risk of damage or deformation.

Space optimization:

Telescopic cylinders contribute to space optimization in manufacturing machinery. Their compact design allows for efficient utilization of available space, especially in equipment with limited footprint. The telescopic nature of the cylinders enables them to retract when not in use, minimizing the space occupied and allowing for better overall layout and arrangement of the machinery.

Advantages of telescopic cylinders in manufacturing machinery:

Telescopic cylinders offer several advantages in material processing applications within manufacturing machinery:

- Material handling and manipulation capabilities

- Precise positioning and alignment of materials

- Adjustable working height for versatility

- Modular design for customization

- Force generation and control for consistent processing

- Space optimization in compact machinery

Overall, telescopic cylinders are widely used in manufacturing machinery for material processing tasks, providing material handling, positioning, and force control capabilities. Their flexibility, modularity, and precise control contribute to efficient and accurate material processing operations in manufacturing.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in manufacturing machinery.

Can you explain the purpose and role of telescopic cylinders in machinery?

Telescopic cylinders play a crucial role in various machinery and equipment applications. Here's a detailed explanation:

Purpose of telescopic cylinders:

Telescopic cylinders are primarily used when an extended stroke length is required while maintaining a compact retracted length. They enable machinery and equipment to achieve extended reach, height adjustment, or lifting capabilities without increasing the overall size or footprint of the cylinder. The purpose of telescopic cylinders is to provide efficient and reliable linear motion in applications that demand long stroke lengths.

Role of telescopic cylinders in machinery:

- Material Handling: Telescopic cylinders are extensively used in material handling machinery, such as cranes, forklifts, and loaders. They enable the extension and retraction of booms, arms, or lifting mechanisms, allowing operators to reach higher or farther to handle and transport materials with ease.

- Dump Trucks and Trailers: Telescopic cylinders are commonly employed in dump trucks and trailers for the tilting and unloading of cargo or bulk materials. The extendable stroke of the cylinder raises the bed or container to dump the contents, enabling efficient unloading and reducing manual labor.

- Aerial Platforms: Telescopic cylinders are essential components in aerial work platforms, such as cherry pickers or scissor lifts. They facilitate the vertical movement and height adjustment of the platform, allowing operators to access elevated work areas safely.

- Construction Equipment: Telescopic cylinders are used in various construction equipment, including excavators, backhoes, and telescopic handlers. They provide the necessary extension and retraction for the boom, arm, or bucket, enabling digging, lifting, and reaching capabilities in construction and earthmoving applications.

- Mobile Equipment: Telescopic cylinders are utilized in mobile equipment, such as telescopic cranes and mobile cranes. They enable the extension and retraction of the boom sections, allowing for increased reach and lifting capacities in lifting and construction operations.

- Specialized Machinery: Telescopic cylinders find application in specialized machinery, such as fire truck aerial ladders, telescopic masts, or telescopic booms in industrial and military equipment. They provide the required extension and retraction for specific tasks, such as firefighting, surveillance, or equipment deployment.

The role of telescopic cylinders in machinery is to provide precise and controlled linear motion, enabling the equipment to perform specific tasks with extended reach, height adjustment, or lifting capabilities. They contribute to the efficiency, versatility, and productivity of machinery in various industries.

It's important to ensure proper selection, installation, and maintenance of telescopic cylinders based on the specific machinery requirements and manufacturer's guidelines to ensure safe and reliable operation.

editor by Dream 2024-05-14