Product Description

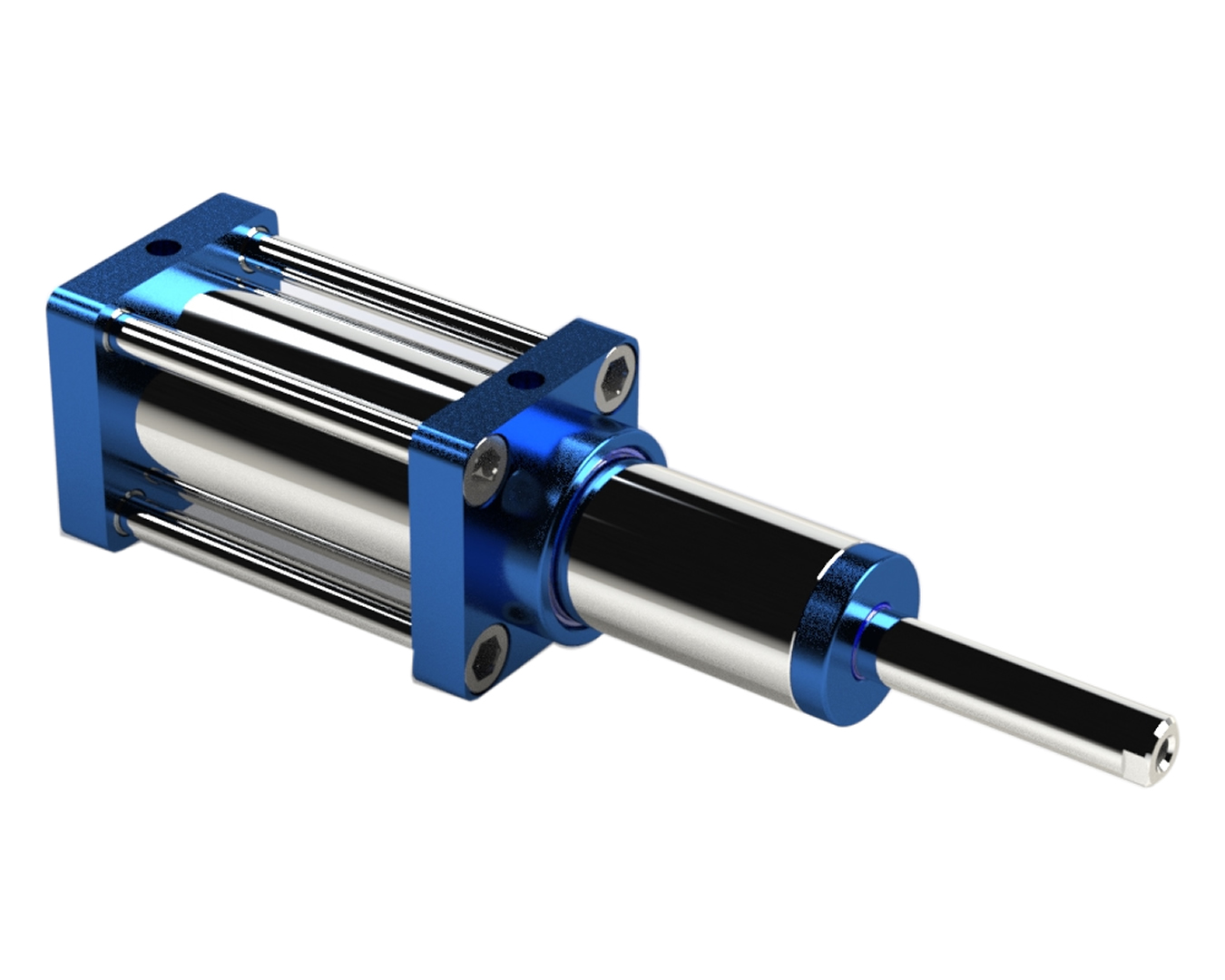

piston long stroke telescopic hydraulic cylinder for sale

1. Describe:

High pressure electric hydraulic cylinder is powered by ZB series of high pressure electric oil pump,

the function for oil pressure rebound, overflow, it is designed a safe protect pressurizer, it can

protect emergent over pressure, especial construction can protect jack. Hydraulic jack can bear

partial loading is 5% of rated pressure. High pressure alloy cylinder is very durable, especially

in the larger project, it is easily to be operated and control. It can be used for lifting heavy machine,

bridge project, hydraulic engineering, harbour construction and other equipment. It has large output,

light weight, remote control and other advantages, it can match with our high pressure oil pump, it

can reach jack, push, pull and extrusion and kinds of working.

2. Technology parameters:

| Model | Tonnage T |

Stroke B-A mm |

Closed height A mm |

Extend height B mm |

Outer diameter of oil cylinder mm |

Dimension of plunger mm |

Dimension of oil pump mm |

Weight kg |

Pressure | Recommend electric oil pump |

| STQ50-100 | 50 | 100 | 225 | 325 | 127 | 70 | 100 | 35 | 63MPA | 50T-200T 0.55KW 0.75KW 1.5KW 3KW 4KW 5.5KW |

| STQ50-160 | 160 | 285 | 445 | 39 | ||||||

| STQ50-200 | 200 | 325 | 525 | 46 | ||||||

| STQ50-300 | 300 | 425 | 725 | 48 | ||||||

| STQ50-500 | 500 | 625 | 1125 | 63 | ||||||

| STQ100-100 | 100 | 100 | 250 | 350 | 180 | 100 | 140 | 58 | 63MPA | |

| STQ100-160 | 160 | 310 | 470 | 63 | ||||||

| STQ100-200 | 200 | 350 | 550 | 78 | ||||||

| STQ100-300 | 300 | 450 | 750 | 96 | ||||||

| STQ100-500 | 500 | 650 | 1150 | 130 | ||||||

| STQ150-100 | 150 | 100 | 260 | 360 | 219 | 125 | 180 | 58 | 63MPA | |

| STQ150-160 | 160 | 320 | 480 | 69 | ||||||

| STQ150-200 | 200 | 360 | 560 | 86 | ||||||

| STQ150-300 | 300 | 460 | 760 | 103 | ||||||

| STQ150-500 | 500 | 660 | 1160 | 255 | ||||||

| STQ200-100 | 200 | 100 | 285 | 385 | 240 | 150 | 200 | 96 | 63MPA | |

| STQ200-160 | 160 | 345 | 505 | 103 | ||||||

| STQ200-200 | 200 | 385 | 585 | 116 | ||||||

| STQ200-300 | 300 | 485 | 785 | 161 | ||||||

| STQ200-500 | 500 | 685 | 1185 | 221 | ||||||

| STQ320-100 | 320 | 100 | 310 | 410 | 330 | 180 | 250 | 196 | 63MPA | 1.5KW 3KW 4KW 5.5KW |

| STQ320-160 | 160 | 370 | 530 | 240 | ||||||

| STQ320-200 | 200 | 410 | 610 | 258 | ||||||

| STQ320-300 | 300 | 510 | 810 | 311 | ||||||

| STQ320-500 | 500 | 710 | 1210 | 456 | ||||||

| STQ400-100 | 400 | 100 | 355 | 455 | 380 | 200 | 290 | 198 | 63MPA | 3KW 4KW 5.5KW 7.5KW |

| STQ400-160 | 160 | 415 | 575 | 231 | ||||||

| STQ400-200 | 200 | 460 | 660 | 264 | ||||||

| STQ400-300 | 300 | 555 | 855 | 367 | ||||||

| STQ400-500 | 500 | 755 | 1255 | 456 | ||||||

| STQ500-100 | 500 | 100 | 360 | 460 | 430 | 200 | 320 | 323 | 63MPA | 3KW 4KW 5.5KW 7.5KW |

| STQ500-160 | 160 | 420 | 580 | 330 | ||||||

| STQ500-200 | 200 | 460 | 660 | 420 | ||||||

| STQ500-300 | 300 | 560 | 860 | 581 | ||||||

| STQ500-500 | 500 | 760 | 1260 | 599 | ||||||

| STQ630-100 | 630 | 100 | 417 | 517 | 500 | 250 | 360 | 560 | 63MPA | 4KW 5.5KW 7.5KW 11KW |

| STQ630-160 | 160 | 477 | 637 | 633 | ||||||

| STQ630-200 | 200 | 517 | 717 | 696 | ||||||

| STQ630-300 | 300 | 617 | 917 | 898 | ||||||

| STQ630-500 | 500 | 817 | 1317 | 1250 | ||||||

| STQ800-100 | 800 | 100 | 488 | 588 | 560 | 300 | 400 | 896 | 63MPA | 7.5KW 11KW |

| STQ800-200 | 200 | 598 | 798 | 1040 | ||||||

| STQ800-300 | 300 | 698 | 998 | 1380 | ||||||

| STQ800-500 | 500 | 898 | 1398 | 1520 | ||||||

| STQ1000-100 | 1000 | 100 | 530 | 630 | 600 | 320 | 450 | 1286 | 63MPA | 7.5KW 11KW |

| STQ1000-200 | 200 | 630 | 830 | 1332 | ||||||

| STQ1000-300 | 300 | 760 | 1060 | 1663 |

3.Application:

Our hydraulic jacks have been widely used for industrial field, such as steel plant, cement industry, chemical and refinery, bridge, railway, highway, hydropower station, ship repair, building, construction and maintenance.

4.Customer Praise:

5.Package:

6.Company information:

HangZhou Lead Equipment Co., Ltd. Have been in hydraulic tools industry since 2009. Our main products as follow:

Single acting hydraulic jack/cylinder/ram (10-100 tons)

Single acting hollow hydraulic jack/cylinder/ram (12-100 tons)

Double acting hydraulic jack/cylinder/ram (50-2000 tons)

Double acting hollow hydraulic jack/cylinder/ram (50-2000 tons)

Single acting hydraulic jack/cylinder/ram with lock nut (55-200 tons)

Thin type single acting hydraulic jack/cylinder/ram (10-200 tons)

Ultrathin hydraulic jack/cylinder/ram (10-200 tons)

Flange type hydraulic jack/cylinder/ram (10-630 tons)

Synchronous hydraulic jack (10-1000 tons)

Hydraulic accessories: high pressure oil hose, couplers, seal kits, mainfold, etc.

All the tonnage, stroke, height can be customized according to client's requirements, supply the best quality and serve. Our warranty is 2 years.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Usage: | Automation and Control |

| Structure: | Plunger Cylinder |

| Power: | Hydraulic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in load capacity and weight?

Telescopic cylinders are designed to handle variations in load capacity and weight effectively. Here's a detailed explanation:

Load-specific design:

Telescopic cylinders are engineered with load-specific design considerations to accommodate variations in load capacity and weight. Manufacturers take into account factors such as the maximum expected load, the range of anticipated loads, and the required safety factors. The cylinder's components, materials, and dimensions are selected and configured accordingly to provide the necessary strength and stability.

Multiple stages:

The nested structure of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for adaptability to different loads. Each stage can handle a specific portion of the load, and the collective capacity of all stages determines the overall load capacity of the cylinder. By adding or removing stages, telescopic cylinders can be customized to suit different load requirements, providing flexibility in handling variations in weight.

Hydraulic system control:

The hydraulic control system of telescopic cylinders plays a vital role in managing variations in load capacity. By regulating the flow of hydraulic fluid to each stage, operators can control the extension and retraction force applied to the cylinder. This control allows for adjustments based on the specific load and weight requirements, ensuring the cylinder operates within its safe working limits.

Pressure relief and overload protection:

Telescopic cylinders are often equipped with pressure relief valves and overload protection mechanisms to safeguard against excessive loads. Pressure relief valves help prevent over-pressurization of the hydraulic system by diverting excess fluid flow, protecting the cylinder from potential damage. Overload protection mechanisms, such as overload sensors or mechanical stops, are designed to activate and halt the cylinder's movement if the load exceeds the safe operating limits.

Load distribution and stability:

Telescopic cylinders contribute to load distribution and stability. The nested design distributes the load across multiple stages, reducing stress on individual components and enhancing overall stability. Proper weight distribution on the machinery or equipment, as well as secure attachment of the load, further contribute to maintaining stability and ensuring safe operation.

It's important to note that while telescopic cylinders can handle variations in load capacity and weight, it is crucial to operate within the specified load limits and follow the manufacturer's guidelines. Exceeding the recommended load capacity can compromise the safety, performance, and longevity of the telescopic cylinder and the machinery it is installed on.

Consulting the manufacturer's documentation, engineering specifications, and relevant industry standards is essential for understanding and adhering to the appropriate load capacity and weight guidelines when using telescopic cylinders.

Can telescopic cylinders be used in agricultural machinery for various tasks?

Yes, telescopic cylinders are widely used in agricultural machinery for various tasks. Here's a detailed explanation:

Versatile applications:

Telescopic cylinders offer versatility and are suitable for a wide range of tasks in agricultural machinery. They are commonly employed in equipment such as tractors, harvesters, sprayers, loaders, and tillers.

Lifting and lowering:

Telescopic cylinders are utilized for lifting and lowering applications in agricultural machinery. They provide the necessary force to raise and lower attachments such as loader buckets, tillage implements, or harvest platforms. The telescopic cylinder's design allows for efficient force transmission, enabling smooth and controlled movement.

Reach extension:

Telescopic cylinders are valuable for extending the reach of agricultural machinery. For example, in a harvester, telescopic cylinders can extend the reach of the harvesting arm, allowing operators to access crops in a broader area. This extension capability increases efficiency and productivity by reducing the need for repositioning the machinery frequently.

Adjustable working height:

Telescopic cylinders are employed in agricultural machinery to provide adjustable working heights. For instance, in sprayers or spreaders, telescopic cylinders can adjust the height of the booms or spreading mechanisms, allowing for precise application of fertilizers, pesticides, or seeds.

Folding and unfolding:

Telescopic cylinders are used to facilitate folding and unfolding actions in agricultural machinery. This is particularly useful for equipment that needs to be transported or stored in compact configurations. For example, telescopic cylinders can fold the wings of a tillage implement for easy transport on roads or through narrow gateways.

Stabilization and leveling:

Telescopic cylinders contribute to the stabilization and leveling of agricultural machinery. They are employed in tasks such as adjusting the height and angle of plows, cultivators, or balers to ensure proper ground engagement and uniform performance.

Advantages of telescopic cylinders in agricultural machinery:

Telescopic cylinders offer several advantages in agricultural machinery:

- Versatility: Telescopic cylinders can be used for various tasks, providing flexibility and adaptability in agricultural operations.

- Efficient force transmission: The telescopic design allows for direct and efficient force transmission, maximizing the equipment's lifting and operational capabilities.

- Precise control: Telescopic cylinders enable precise control over movements, allowing for accurate positioning and improved productivity.

- Space optimization: Telescopic cylinders contribute to space optimization by enabling folding or compact configurations, facilitating transportation and storage of agricultural machinery.

Overall, telescopic cylinders are valuable components in agricultural machinery, offering versatility, efficient force transmission, precise control, and space optimization. They enhance the functionality and productivity of agricultural equipment across various tasks and applications.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in agricultural machinery.

How does a telescopic cylinder contribute to precise reach and positioning?

A telescopic cylinder plays a crucial role in achieving precise reach and positioning in various applications. Here's a detailed explanation:

Nested structure:

The nested structure of a telescopic cylinder, consisting of multiple stages or sleeves that retract inside one another, enables precise reach and positioning. Each stage can be extended or retracted individually, allowing for incremental adjustments in the cylinder's length. This modular design provides fine-tuning capabilities, enabling operators to achieve the desired reach and positioning with accuracy.

Controlled extension and retraction:

The hydraulic control system of a telescopic cylinder ensures controlled extension and retraction of the stages. By regulating the flow of hydraulic fluid to each stage, operators can precisely control the speed and movement of the cylinder. This control allows for smooth and gradual extension or retraction, facilitating precise reach and positioning without abrupt or jerky movements.

Adjustable stroke length:

Telescopic cylinders offer the advantage of adjustable stroke length. The hydraulic system can be adjusted to vary the extension and retraction distance, allowing for customization based on the specific reach and positioning requirements of the application. This adjustability enables operators to adapt the cylinder's stroke length to different tasks and working conditions, ensuring precise and optimized reach.

Position feedback systems:

In some applications, telescopic cylinders may be equipped with position feedback systems. These systems utilize sensors or transducers to provide real-time feedback on the cylinder's extension or retraction position. By monitoring the position, operators can precisely track and control the reach and positioning of the cylinder, enhancing accuracy and repeatability.

Stability and rigidity:

Telescopic cylinders are designed to maintain stability and rigidity during operation. The nested structure, along with the hydraulic system, helps minimize unwanted oscillations or vibrations that could affect reach and positioning accuracy. This stability ensures that the cylinder maintains its intended position without undesired movement or deflection.

Overall, a telescopic cylinder contributes to precise reach and positioning through its nested structure, controlled extension and retraction, adjustable stroke length, position feedback systems (if equipped), and stability. These features enable operators to achieve accurate and repeatable reach and positioning in various applications.

It's important to consult the manufacturer's guidelines and specifications, as well as follow proper maintenance practices, to ensure the reliable and precise performance of telescopic cylinders in achieving reach and positioning requirements.

editor by CX 2024-02-11