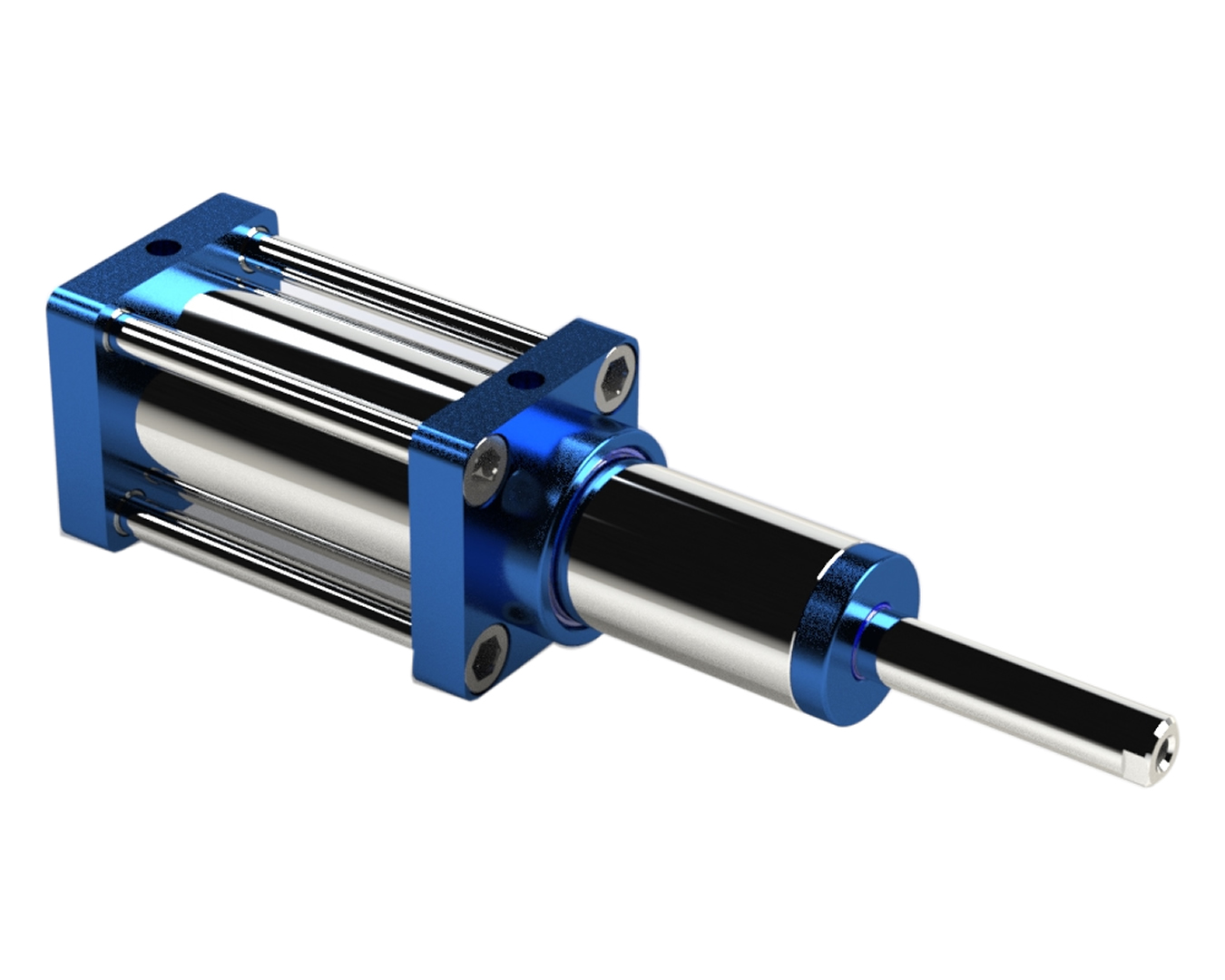

Product Description

Front End Loader Hydraulic Telescopic Cylinder Manufacturer

| Model | The first stage rod diameter | Stroke | Closed length | Open length |

| WTPK 3TG F5*72 | 5" | 1829mm | 945mm | 2773mm |

| WTPK 3TG F5*84 | 5" | 2134mm | 1046mm | 3180mm |

| WTPK 3TG F5*107 | 5" | 158/136/116/95 | 1229mm | 3961mm |

| WTPK 3TG F5*126 | 5" | 3216mm | 1386mm | 4602mm |

| WTPK 3TG F6*86 | 6" | 3216mm | 1038mm | 3241mm |

| WTPK 3TG F6*104 | 6" | 2640mm | 1194mm | 3834mm |

| WTPK 3TG F6*107 | 6" | 2732mm | 1289mm | 3961mm |

| WTPK 3TG F6*111 | 6" | 2819mm | 1268mm | 4087mm |

| WTPK 3TG F6*120 | 6" | 3048mm | 1359mm | 4407mm |

| WTPK 3TG F6*126 | 6" | 3208mm | 1386mm | 4594mm |

| WTPK 3TG F6*140 | 6" | 3562mm | 1519mm | 5081mm |

| WTPK 4TG F6*135 | 6" | 3429mm | 1199mm | 4628mm |

| WTPK 4TG F6*156 | 6" | 3962mm | 1362mm | 5324mm |

| WTPK 3TG F7*110 | 7" | 2810mm | 1271mm | 4081mm |

| WTPK 3TG F7*120 | 7" | 3048mm | 1349mm | 4397mm |

| WTPK 3TG F7*124 | 7" | 3172mm | 1392mm | 4564mm |

| WTPK 3TG F7*129 | 7" | 3277mm | 1435mm | 4712mm |

| WTPK 3TG F7*140 | 7" | 3567mm | 1524mm | 5091mm |

| WTPK 3TG F7*150 | 7" | 3810mm | 1613mm | 5423mm |

| WTPK 4TG F7*120 | 7" | 3048mm | 1349mm | 4168mm |

| WTPK 4TG F7*135 | 7" | 3429mm | 1230mm | 4659mm |

| WTPK 4TG F7*140 | 7" | 3556mm | 1263mm | 4819mm |

| WTPK 4TG F7*156 | 7" | 3962mm | 1365mm | 5327mm |

| WTPK 4TG F7*161 | 7" | 4108mm | 1405mm | 5513mm |

| WTPK 4TG F7*167 | 7" | 4242mm | 1432mm | 5674mm |

| WTPK 4TG F7*180 | 7" | 4572mm | 1552mm | 6124mm |

| WTPK 4TG F8*148 | 8" | 3753mm | 1308mm | 5061mm |

| WTPK 4TG F8*156 | 8" | 3962mm | 1365mm | 5327mm |

| WTPK 4TG F8*161 | 8" | 4064mm | 1416mm | 5480mm |

| WTPK 4TG F8*170 | 8" | 4318mm | 1454mm | 5481mm |

| WTPK 4TG F8*180 | 8" | 4572mm | 1518mm | 6090m |

| WTPK 5TG F8*170 | 8" | 4318mm | 1267mm | 5585mm |

| WTPK 5TG F8*190 | 8" | 4800mm | 1387mm | 6188mm |

| WTPK 5TG F8*220 | 8" | 5588mm | 1524mm | 7122mm |

| WTPK 5TG F8*235 | 8" | 5944mm | 1641mm | 7585mm |

| WTPK 5TG F8*250 | 8" | 6325mm | 1743mm | 8068mm |

| WTPK 5TG F9*265 | 9" | 6731mm | 1844mm | 8575mm |

| WTPK 5TG F9*280 | 9" | 7112mm | 1997mm | 9109mm |

| WTPK 5TG F9*300 | 9" | 7620mm | 2007mm | 9627mm |

| WTPK 5TG F9*320 | 9" | 8129mm | 2108mm | 9628mm |

| WTPK 5TG F9*340 | 9" | 8636mm | 2210mm | 10846mm |

| Cylinder Tube O.D. | 6.03"(153.2mm)--10.50"(266.70mm) |

| Operating Pressure | 3000PSI (207Bar) |

| Numbers of Stage | 3, 4, 5 |

| Largest Moving Stage Diameter | 5.0" (127mm)--9.0"(228.60mm) |

| Stroke | 71.94"(1827.30mm)--339.88"(8632.95mm) |

| Closed Length | 36.62"(930.10mm)--90.62"(2301.70mm) |

| Extended Length | 108.56"(2757.40mm)--430.50"(1571.70mm) |

| Base Mount Width | 7.00" (177.80mm)--10.68"(271.30mm) |

| Base Mount Diameter | 2.06"(52.30mm)--2.12"(53.80mm) |

| Plunger Mount Diameter | 2.00"(50.80mm) |

| Plunger Mount Thickness | 2.03"(51.60mm) |

| Warranty Period | 14 months after date of production |

Company Introduction:

ZheJiang CHINAMFG hydraulic co., ltd. sets up in 1994, is a specialized custom hydraulic cylinder for tipper truck manufacturing enterpirise which takes up with design, manufacturer, sell hydraulic products. The company covers an area of 180,000 square meters, with 500 emplayees in it. There are 700 sets of manufacturing equipments, such as cold drawing production lines, surface treatment production line, boring and rolling production line, various of digital-control machining and testing equipment.

Production advantages:

1.The North American advanced processing technology is adopted to ensure the stable performance.

2.High quality alloy seamless steel pipe are adopted to keep big lifting capacity and light weight;

3.The application of imperial size makes it easy to replace the seals and other accessories;

4.Superior chrome-plating technology improves the corrosion resistance and hardness of cylinders;

5.The world famous brands of seals such as HALLITE, CHINAMFG and NOK ensure the sealing performance;

>Professional manufacturer& supplier of Hydraulic Cylinders for more than 22 years;

>Hydraulic Cylinders Certification ISO9001:2008, SGS, TS16949, RoHS, CNAS Certification;

>Experience in export North America, Australia, Asia, Middle East, Africa;

>Hydraulic Cylinders can be Make according to client's requirements;

>The Hydraulic Cylinders can be used for Dump Truck, Tipper Truck, Trailer, Agricultural Machinery, Engineering Machinery, Garbage Truck, Landing Platform etc;

>We are the supplier of Sinotruk, CNHTC, CIMC, Wuzheng, Beiben Truck, Baic Group, FOTON, HOWO, JAC, ZheJiang Hyundai, Xihu (West Lake) Dis.n, ZheJiang Automobile, most of famous truck manufacturing and refitting company use our telescopic cylinder as first choice.

Exhibitions& Customers:

>We are the supplier of Sinotruk, CNHTC, CIMC, Wuzheng, Beiben Truck, Baic Group, FOTON, HOWO, JAC, ZheJiang Hyundai, Xihu (West Lake) Dis.n, ZheJiang Automobile, most of famous truck manufacturing and refitting company use our telescopic cylinder as first choice.

>We attended each Bauma exhibition, the world grade fair for construction equipments, building material machines, mining machines and earn much more opportunity to extend our business to oversea market.

Quality Control:

>All specification is designed by professional engineer.

>All material is high quality-Seal kits were purchased from USA, Japan, UK and Sweden.

>All material is processed by skilled workers and advanced CNC lathe

>All cylinders are 100% tested before package to ensure every cylinder is qualified for its purpose

>Package is air cushion film for each cylinder and steel case for all cylinders to ensure goods can arrive at customer safely

>One year warranty and long time track service is offered to solve any problems you meet after sale.

Guarantee and after sale service:

>7 x 24 hours technical support through email

>Goods will be delivered safely on time

>One year guarantee after destination port arrival

>Life long time track service

FAQ:

Q1. What are the same aspects of your cylinder with CHINAMFG cylinder?

A: Same inside structure.

Same outside dimension and same mounting sizes. It can be interchangeable with Hyva's

Q2. Compared with CHINAMFG cylinder, what are your cylinder advantages?

A: 1. Rod are chrome plated.

2. Tubes are quenched and tempered.

3. Tube inner hole goes through deephole boring machine processing. Surface roughness is 0.4Ra

and circular degree is 0.571.

4. Good quality yet lower price.

Q3: Are you a manufacture or a trade company?

A: Manufacture, we are the leader manufacturer of hydraulic industry in China with 20 years' experience and technology accumulation. With strong technical team we could solve any annoyance of you.

Q4: Do you have quality control system?

A: Yes, The quality management system introduced is: ISO/TS 16949:2009-certified by NQA and IATF cert.

Q5: How can i get a booklet and buy a cylinder from you?

A: Very easy! Just leave me a message or email or call me directly, let me know you are interesting in our products. I will talk with you for the details soon!

Q6: Can you tell me the price for the cylinder?

A: 1. Please advice the drawing with technical requirement.

2. Please advice the model No. after you check our booklet.

3. Please advice the tipping capacity, number of stages, closed length, mounting type and size.

4. Please also help advice the quantities, this is very important.

Q7: Do your products come with a warranty?

A: Yes, we have 1 year warranty. In this year, if the quality problem we will free repair for you.

Q8: Hydraulic cylinder internal leakage?

A: 3 main reasons causing internal leakage: Overload, polishing bad controlled, cheap seal kits. As is known to all, vehicles in China are often overloaded, our products all designed to bear the overload power. Advanced equipment could assure the polish processing. And we use the imported/TOP brand seals to meet customers' requirement.

Q9: What about the quality feedback of your products?

A: WE HAVE NEVER RECEIVED EVEN ONCE QUALITY COMPLAINT FOR MANY YEARS OF INTERNATIONAL BUSINESS.

Q10: Can you help me to install or recommend what kind of hydraulic cylinder or power pack should I use for specific machine?

A: Yes, we have 25 experienced engineers who are always ready to help you. If you do not know what kind of hydraulic cylinders should be used in your machine, please just contact us, our engineers will design the exact products match your need.

Q11: What is the delivery time?

A: Within 20 days for samples.

15-30 days for bulk production, which is depend on quality, production process and so on.

Q12: What is your main payment term?

A: T/T, L/C, D/A, D/P either is available.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Usage: | Garbage Truck |

| Structure: | General Cylinder |

| Power: | Hydraulic |

| Standard: | Standard, Nonstandard |

| Working Pressure: | 16MPa |

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in load capacity and weight?

Telescopic cylinders are designed to handle variations in load capacity and weight effectively. Here's a detailed explanation:

Load-specific design:

Telescopic cylinders are engineered with load-specific design considerations to accommodate variations in load capacity and weight. Manufacturers take into account factors such as the maximum expected load, the range of anticipated loads, and the required safety factors. The cylinder's components, materials, and dimensions are selected and configured accordingly to provide the necessary strength and stability.

Multiple stages:

The nested structure of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for adaptability to different loads. Each stage can handle a specific portion of the load, and the collective capacity of all stages determines the overall load capacity of the cylinder. By adding or removing stages, telescopic cylinders can be customized to suit different load requirements, providing flexibility in handling variations in weight.

Hydraulic system control:

The hydraulic control system of telescopic cylinders plays a vital role in managing variations in load capacity. By regulating the flow of hydraulic fluid to each stage, operators can control the extension and retraction force applied to the cylinder. This control allows for adjustments based on the specific load and weight requirements, ensuring the cylinder operates within its safe working limits.

Pressure relief and overload protection:

Telescopic cylinders are often equipped with pressure relief valves and overload protection mechanisms to safeguard against excessive loads. Pressure relief valves help prevent over-pressurization of the hydraulic system by diverting excess fluid flow, protecting the cylinder from potential damage. Overload protection mechanisms, such as overload sensors or mechanical stops, are designed to activate and halt the cylinder's movement if the load exceeds the safe operating limits.

Load distribution and stability:

Telescopic cylinders contribute to load distribution and stability. The nested design distributes the load across multiple stages, reducing stress on individual components and enhancing overall stability. Proper weight distribution on the machinery or equipment, as well as secure attachment of the load, further contribute to maintaining stability and ensuring safe operation.

It's important to note that while telescopic cylinders can handle variations in load capacity and weight, it is crucial to operate within the specified load limits and follow the manufacturer's guidelines. Exceeding the recommended load capacity can compromise the safety, performance, and longevity of the telescopic cylinder and the machinery it is installed on.

Consulting the manufacturer's documentation, engineering specifications, and relevant industry standards is essential for understanding and adhering to the appropriate load capacity and weight guidelines when using telescopic cylinders.

Can telescopic cylinders be used in aerial work platforms for extended reach?

Yes, telescopic cylinders are commonly used in aerial work platforms to achieve extended reach. Here's a detailed explanation:

Increased working height:

Telescopic cylinders enable aerial work platforms to reach greater heights compared to other types of lifting mechanisms. The multi-stage design of telescopic cylinders allows for sequential extension, providing incremental increases in working height. This extended reach capability is crucial for accessing elevated areas such as construction sites, maintenance tasks, or elevated platforms.

Flexible reach adjustment:

Telescopic cylinders offer flexibility in adjusting the reach of aerial work platforms. By extending or retracting the cylinders, operators can modify the platform's horizontal reach according to the specific job requirements. This flexibility allows for precise positioning of the platform, ensuring safe and efficient access to work areas at varying distances from the base.

Stability and load capacity:

Telescopic cylinders contribute to the stability and load capacity of aerial work platforms during extended reach operations. The cylinders provide structural support and help distribute the weight of the platform and the load being lifted. This load distribution ensures stability, minimizes the risk of tipping or tilting, and allows for safe operation even at maximum reach.

Controlled movements:

Telescopic cylinders enable controlled and smooth movements of aerial work platforms. The hydraulic control system regulates the extension and retraction of the cylinders, allowing for precise control over the platform's vertical and horizontal motions. This controlled movement enhances operator safety, minimizes vibrations, and enables accurate positioning of the platform during extended reach tasks.

Compact design:

Telescopic cylinders offer a compact design that allows for efficient integration into aerial work platforms. The cylinders can be retracted when not in use, minimizing the space occupied by the lifting mechanism. This compactness allows for better maneuverability, improved accessibility in confined spaces, and efficient transportation of the aerial work platform.

Integration with other platform features:

Telescopic cylinders can be integrated with other features of aerial work platforms to enhance functionality. For example, they can be combined with articulating booms or rotating platforms to achieve versatile reach and positioning capabilities. This integration expands the range of applications for aerial work platforms, enabling them to navigate obstacles, reach over obstacles, or access difficult-to-reach areas.

Advantages of telescopic cylinders in aerial work platforms:

Telescopic cylinders offer several advantages when used in aerial work platforms for extended reach:

- Increased working height for accessing elevated areas

- Flexible reach adjustment for precise positioning

- Stability and load capacity during extended reach

- Controlled movements for operator safety

- Compact design for maneuverability and transportation

- Integration with other platform features for enhanced functionality

Overall, telescopic cylinders are a reliable and efficient choice for achieving extended reach in aerial work platforms. Their ability to increase working height, provide flexibility in reach adjustment, ensure stability, enable controlled movements, offer a compact design, and integrate with other platform features makes them well-suited for a wide range of aerial work applications.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in aerial work platforms.

What industries commonly use telescopic cylinders in their applications?

Telescopic cylinders find applications in a wide range of industries where extended reach, height adjustment, or lifting capabilities are required. Here's a detailed explanation:

Industries commonly using telescopic cylinders:

- Construction: The construction industry extensively utilizes telescopic cylinders in various equipment, including excavators, backhoes, loaders, cranes, and concrete pumps. Telescopic cylinders enable the extension and retraction of booms, arms, or buckets, providing the necessary reach, digging, and lifting capabilities in construction and earthmoving applications.

- Material Handling and Logistics: Telescopic cylinders are essential in industries involved in material handling and logistics operations. This includes applications such as cranes, forklifts, loaders, conveyor systems, and automated storage and retrieval systems. Telescopic cylinders enable the lifting, tilting, or extending movements required for efficient loading, unloading, and transportation of materials.

- Agriculture: The agricultural sector employs telescopic cylinders in various machinery, such as tractors, harvesters, sprayers, and irrigation systems. Telescopic cylinders facilitate height adjustment, folding/unfolding of implements, and movement of equipment parts, enhancing productivity and efficiency in agricultural operations.

- Transportation and Automotive: Telescopic cylinders play a role in the transportation and automotive industries. They are used in applications such as dump trucks, trailers, refuse trucks, car haulers, and hydraulic ramps. Telescopic cylinders enable the efficient tilting, dumping, or lifting of cargo, enhancing the functionality and versatility of transportation equipment.

- Marine and Offshore: The marine and offshore industries utilize telescopic cylinders in applications such as ship cranes, offshore platforms, and subsea equipment. Telescopic cylinders enable the extension and retraction of booms, arms, or lifting mechanisms, supporting various marine operations including cargo handling, offshore construction, and underwater exploration.

- Mining and Quarrying: In mining and quarrying operations, telescopic cylinders are employed in equipment such as excavators, loaders, and conveyor systems. They facilitate the necessary extension and retraction movements for digging, lifting, and conveying materials, enhancing productivity and efficiency in mining operations.

- Utilities and Energy: The utilities and energy sectors utilize telescopic cylinders in applications such as utility trucks, aerial platforms, power line maintenance equipment, and renewable energy installations. Telescopic cylinders enable the safe and efficient access to elevated work areas, equipment maintenance, and positioning of components in energy infrastructure.

- Manufacturing and Industrial: Telescopic cylinders are found in manufacturing and industrial environments in various machinery, including automated systems, assembly lines, robotic arms, and material handling equipment. They provide the necessary linear motion and reach for precise positioning, lifting, or transferring of components during manufacturing processes.

These are just a few examples of industries that commonly use telescopic cylinders in their applications. The versatility and efficiency of telescopic cylinders make them valuable components in numerous sectors where extended stroke lengths or compact retracted lengths are required.

It's important to consult industry-specific guidelines and regulations to ensure the proper selection, installation, and maintenance of telescopic cylinders based on the specific application requirements.

editor by Dream 2024-05-14