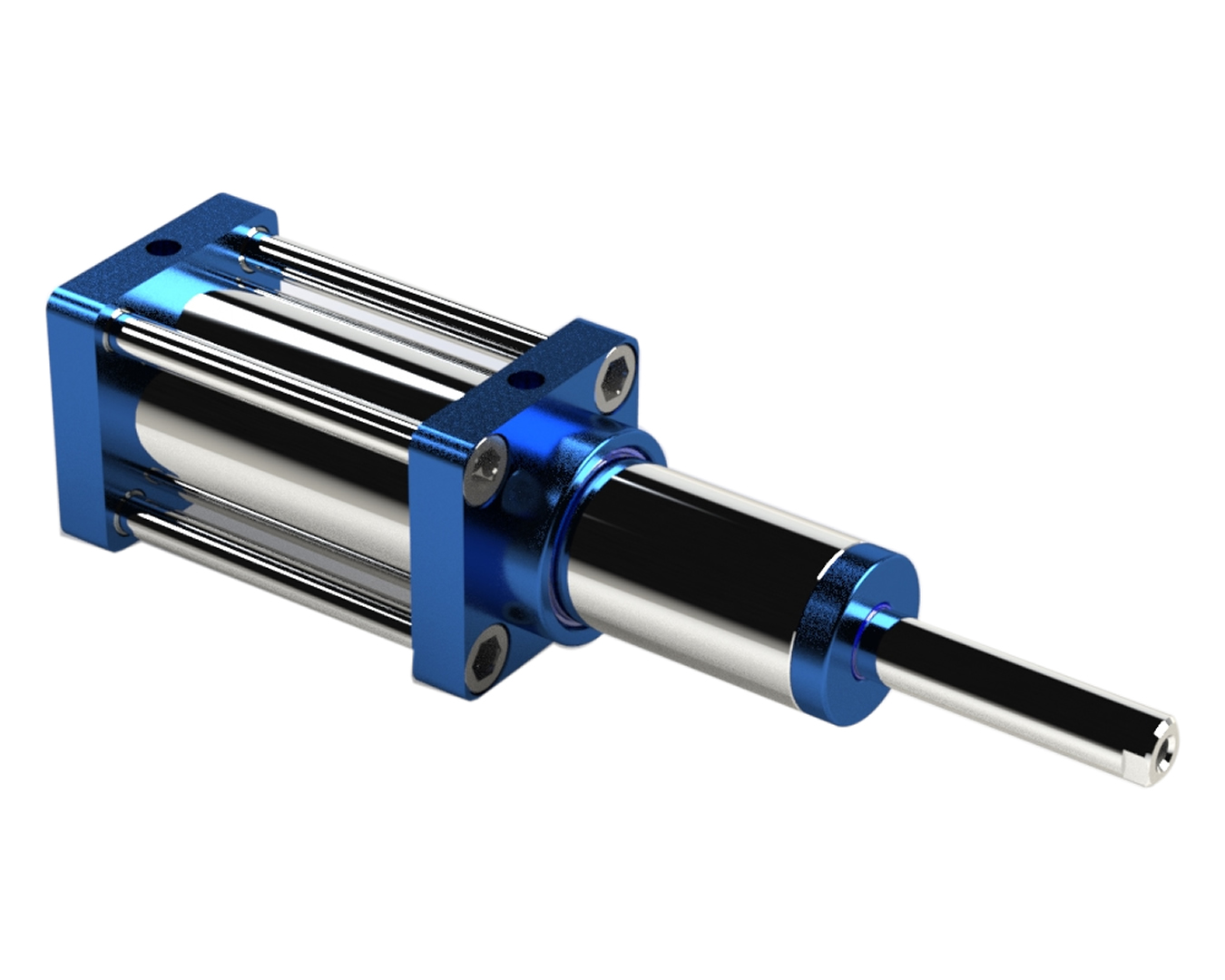

Product Description

Parker Telescopic Hydraulic Dump Truck/Trailer Cylinder/Roll-Off hoist

Features

·Parker Seal Division-"Zero-leak" Sealing Package

·100,000 Yield Induction Hardened Chrome Plated Rod as Standard

·Skived and Burnished Tubing

·Hardened Pin-eye Bushings

·Parker"Zero-leak" Internal Bypass Piston Design

·Greater Rod Support

Benefits

·Leak Free Extended Life

·More Resilient to External Damage

·Consistant Quality

·Extends Cylinder Life as Cylinder Wears

·More Efficient/Less Heat

·Resiste rod Deflection and Side Loading

| Part Description | |

| Application | Dump truck, Tipping, Trailer, Underbody, Roll-off Hoist |

| Material of cylinder tube | 45 steel,27SiMn, Carbon steel, Alloy steel, and general seamless steel |

| Seal | Hallite,SKF,NOK,Guarnitec,Parker,and other equivalent brands |

| Coating | Hard Chrome 0.03-0.05mm |

| Temperature | _30°C to +100°C |

| Working Pressure | 16Mpa-20Mpa |

| Stroke | 2755mm-8530mm |

| Color | as Customer's Requirement |

| Mounting type | Earring-trunnion,double trunnion,double earring(eye end) |

| Plunger | 20#,45# steel with a high frequency quenching |

| Certification | ISO/TS 16949,ISO9001,ABS,API,SGS |

| Package | Shrink film, pallet, plywood case |

| Warranty | 12 months |

| Delivery time | 25-30 days after down payment |

| SKU# | |

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

CHINAMFG team considers all your concerns to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

Why choose us?

Roca team considers all your concerns to suit your hydraulic cylinder requirements. We work out the best design solution for your application.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get a delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer's samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Single Acting |

| Working Method: | Rotary |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in load capacity and weight?

Telescopic cylinders are designed to handle variations in load capacity and weight effectively. Here's a detailed explanation:

Load-specific design:

Telescopic cylinders are engineered with load-specific design considerations to accommodate variations in load capacity and weight. Manufacturers take into account factors such as the maximum expected load, the range of anticipated loads, and the required safety factors. The cylinder's components, materials, and dimensions are selected and configured accordingly to provide the necessary strength and stability.

Multiple stages:

The nested structure of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for adaptability to different loads. Each stage can handle a specific portion of the load, and the collective capacity of all stages determines the overall load capacity of the cylinder. By adding or removing stages, telescopic cylinders can be customized to suit different load requirements, providing flexibility in handling variations in weight.

Hydraulic system control:

The hydraulic control system of telescopic cylinders plays a vital role in managing variations in load capacity. By regulating the flow of hydraulic fluid to each stage, operators can control the extension and retraction force applied to the cylinder. This control allows for adjustments based on the specific load and weight requirements, ensuring the cylinder operates within its safe working limits.

Pressure relief and overload protection:

Telescopic cylinders are often equipped with pressure relief valves and overload protection mechanisms to safeguard against excessive loads. Pressure relief valves help prevent over-pressurization of the hydraulic system by diverting excess fluid flow, protecting the cylinder from potential damage. Overload protection mechanisms, such as overload sensors or mechanical stops, are designed to activate and halt the cylinder's movement if the load exceeds the safe operating limits.

Load distribution and stability:

Telescopic cylinders contribute to load distribution and stability. The nested design distributes the load across multiple stages, reducing stress on individual components and enhancing overall stability. Proper weight distribution on the machinery or equipment, as well as secure attachment of the load, further contribute to maintaining stability and ensuring safe operation.

It's important to note that while telescopic cylinders can handle variations in load capacity and weight, it is crucial to operate within the specified load limits and follow the manufacturer's guidelines. Exceeding the recommended load capacity can compromise the safety, performance, and longevity of the telescopic cylinder and the machinery it is installed on.

Consulting the manufacturer's documentation, engineering specifications, and relevant industry standards is essential for understanding and adhering to the appropriate load capacity and weight guidelines when using telescopic cylinders.

Can telescopic cylinders be used in forestry equipment for tree handling?

Yes, telescopic cylinders are commonly used in forestry equipment for tree handling tasks. Here's a detailed explanation:

Tree felling and extraction:

Telescopic cylinders play a vital role in tree felling and extraction operations. They are utilized in equipment such as feller bunchers, harvesters, and forwarders. Telescopic cylinders provide the necessary force to cut down trees and extract them from the forest. The cylinders are used in combination with cutting heads, grapples, or clamps to grip, hold, and manipulate trees during the felling and extraction processes.

Boom and arm extension:

In forestry equipment, telescopic cylinders are employed to extend the booms and arms of machinery. This extension capability allows operators to reach trees located at various distances and heights, facilitating efficient tree handling. Telescopic cylinders enable the equipment to adapt to different tree sizes and positions, enhancing productivity and reducing manual labor.

Precise control:

Telescopic cylinders provide precise control over tree handling movements. The hydraulic control system allows operators to extend and retract the cylinders with accuracy, enabling controlled positioning of trees during felling, extraction, or stacking. This precise control is crucial for ensuring operator safety, preventing damage to the equipment or surrounding environment, and optimizing operational efficiency.

Load handling and stacking:

Telescopic cylinders support load handling and stacking operations in forestry equipment. They provide the necessary lifting force to handle tree logs and facilitate stacking for transportation or processing. The cylinders work in conjunction with grapples, forks, or other attachments to securely grip and manipulate tree logs during loading, unloading, or stacking activities.

Stability and balance:

Telescopic cylinders contribute to the stability and balance of forestry equipment during tree handling tasks. The controlled extension and retraction of the cylinders help maintain the proper weight distribution and prevent tipping or imbalance when handling heavy tree logs. This ensures the safety of operators and equipment in challenging forestry environments.

Advantages of telescopic cylinders in forestry equipment:

Telescopic cylinders offer several advantages in tree handling applications:

- Enhanced reach: Telescopic cylinders enable extended reach, allowing operators to access trees at various distances and heights.

- Precise control: The hydraulic control system provides precise control over tree handling movements, ensuring accurate positioning and manipulation.

- Efficient load handling: Telescopic cylinders provide the necessary force for lifting, holding, and stacking tree logs, improving efficiency in forestry operations.

- Adaptability: The extension capability of telescopic cylinders allows for adaptation to different tree sizes and positions, enhancing versatility in tree handling tasks.

- Stability and safety: Telescopic cylinders contribute to equipment stability and operator safety by maintaining proper weight distribution during tree handling activities.

Overall, telescopic cylinders are widely used in forestry equipment for tree handling tasks, offering extended reach, precise control, efficient load handling, adaptability, and stability. They enhance the productivity, safety, and efficiency of forestry operations.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in forestry equipment.

What are the components and design features of a telescopic cylinder?

A telescopic cylinder consists of various components and incorporates specific design features to enable its functionality and performance. Here's a detailed explanation:

Components of a telescopic cylinder:

- Stages or Sleeves: A telescopic cylinder comprises multiple stages or sleeves that are nested inside one another. These stages are usually cylindrical in shape and are made of high-strength steel or aluminum alloy. The number of stages can vary depending on the specific design and application requirements.

- Piston and Rod: Each stage of a telescopic cylinder has its own piston and rod assembly. The piston is located inside the stage and is connected to the rod, which extends through the center of the stage. The piston and rod assembly is responsible for generating the linear motion of each stage during extension and retraction.

- Seals: Sealing elements, such as O-rings or lip seals, are used to ensure a hydraulic seal between the stages. These seals prevent leakage of hydraulic fluid and maintain pressure within each stage during operation. The seals also help to protect the internal components from contaminants.

- Locking Mechanism: Telescopic cylinders often incorporate a locking mechanism to secure the extended stages in position. This mechanism ensures stability and prevents unintentional retraction of the cylinder under load. The locking mechanism can be mechanical, hydraulic, or a combination of both, depending on the design and application requirements.

- Guides and Bearings: To maintain proper alignment and minimize friction between the stages, telescopic cylinders may include guides and bearings. These components facilitate smooth extension and retraction of the stages and provide structural support.

- Hydraulic Connections: Telescopic cylinders have hydraulic connections to supply hydraulic fluid for extension and retraction. These connections typically include ports or fittings for the inlet and outlet of hydraulic fluid. Flexible hydraulic hoses or tubing are used to connect the cylinder to the hydraulic system of the equipment.

Design features of a telescopic cylinder:

- Nested Structure: The nested structure is a fundamental design feature of a telescopic cylinder. It allows the stages to extend and retract within one another, enabling a longer stroke length while maintaining a compact retracted length.

- Articulation Capability: Some telescopic cylinders incorporate articulation capability, which allows the cylinder to adjust its angle or position relative to the equipment. This feature enhances the versatility of the cylinder and enables it to adapt to different mounting orientations and working conditions.

- Internal Flow Paths: The design of a telescopic cylinder includes internal flow paths that facilitate the controlled flow of hydraulic fluid between the stages during extension and retraction. These flow paths ensure synchronized movement of the stages and contribute to the overall performance and stability of the cylinder.

- Surface Treatment: The external surfaces of telescopic cylinders are often treated or coated to provide protection against corrosion, wear, and environmental elements. Common surface treatments include painting, powder coating, or electroplating.

These components and design features work together to enable the functionality, reliability, and performance of a telescopic cylinder. It's important to consult the manufacturer's guidelines and specifications for proper installation, operation, and maintenance of the telescopic cylinder based on the specific application requirements.

editor by CX 2024-04-03