Product Description

Product description:

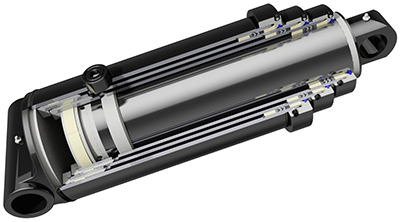

Junfu is famous brand in front-end cylinders, offering an extensive catalogue from 5 to 100 tons with bespoke solutions. Designed for rear-end tippers and tippers trailers, CHINAMFG brand front-end telescopic cylinders are known for their durability, reliability in all conditions and value for money. We believe in delivering a solution that can rapidly and successfully meet your requirements in demanding industries such as transportation, construction and mining. With high payload and longer service intervals for increased operating time, CHINAMFG brand front-end cylinders are also environmentally friendly solutions with lower oil & fuel consumption.

FC telescopic front-end(front mounting) cylinders are primarily designed for straight headboard dump trucks with a capacity range of over 100 tons tipping weight. Our trunnion type FC cylinder is lightweight, strong, maintenance free and offers the most added stability to the tipper. The CHINAMFG brand FC tipping cylinders have earned reputation for their reliability and value for money over many years.

Designed for Dump Truck applications, FC series cylinder with 3-7 stages is capable of lifting more weight which in return allows trucks to be equipped with smaller cylinders reducing space and saving weight. This CHINAMFG series cylinder is mostly used in combination with a Straight Headboard Type and Trunnion Type Body Connection.

The hydraulic system including hydraulic oil tank, gear pump, lift valve, air control valve and limit valve, oil pipe and joints.

Product Details

| series | model |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

ΦA |

Pipe joint |

Applicable cargo box length(mm) |

Overhang length(mm) |

Lifting angle |

Lifting weight(Kg) |

Fuel tank selection |

|

1 3 7 |

3TG-F137*3830 |

200 |

65 |

360 |

60 |

325 |

1585 |

Φ60 |

G1 |

4700-5300 |

800 |

47-52° |

43 |

80 |

|

4TG-F137*3830 |

200 |

65 |

360 |

60 |

325 |

1270 |

Φ60 |

G1 |

4700-5300 |

800 |

47-52° |

31 |

80 |

|

|

4TG-F137*4280 |

200 |

65 |

360 |

60 |

325 |

1390 |

Φ60 |

G1 |

5300-6000 |

800 |

47-52° |

36 |

80 |

|

|

4TG-F137*4800 |

200 |

65 |

360 |

60 |

325 |

1510 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

36 |

80 |

|

|

1 5 7 |

4TG-F157*4280 |

245 |

65 |

360 |

60 |

325 |

1385 |

Φ60 |

G1 |

5300-5800 |

800 |

47-52° |

53 |

80 |

|

4TG-F157*4800 |

245 |

65 |

360 |

60 |

325 |

1505 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

53 |

100 |

|

|

4TG-F157*5100 |

245 |

65 |

360 |

60 |

325 |

1580 |

Φ60 |

G1 |

6200-6800 |

800 |

47-52° |

58 |

100 |

|

|

4TG-F157*5390 |

245 |

65 |

360 |

60 |

325 |

1655 |

Φ60 |

G1 |

6600-7200 |

800 |

47-52° |

58 |

100 |

|

|

5TG-F157*4050 |

245 |

65 |

360 |

60 |

325 |

1125 |

Φ60 |

G1 |

5000-5500 |

800 |

47-52° |

46 |

80 |

|

|

5TG-F157*4280 |

245 |

65 |

360 |

60 |

325 |

1165 |

Φ60 |

G1 |

5300-6000 |

800 |

47-52° |

46 |

80 |

|

|

5TG-F157*4800 |

245 |

65 |

360 |

60 |

325 |

1265 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

49 |

80 |

|

|

5TG-F157*5100 |

245 |

65 |

360 |

60 |

325 |

1340 |

Φ60 |

G1 |

6200-6800 |

800 |

47-52° |

49 |

80 |

|

|

5TG-F157*5390 |

245 |

65 |

360 |

60 |

325 |

1385 |

Φ60 |

G1 |

6600-7200 |

800 |

47-52° |

49 |

80 |

|

|

1 7 9 |

4TG-F179*4600 |

245 |

65 |

360 |

65 |

325 |

1455 |

Φ60 |

G1 |

5600-6300 |

800 |

47-52° |

66 |

120 |

|

4TG-F179*4800 |

245 |

65 |

360 |

65 |

325 |

1505 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

66 |

120 |

|

|

4TG-F179*5100 |

245 |

65 |

360 |

65 |

325 |

1580 |

Φ60 |

G1 |

6200-6800 |

800 |

47-52° |

70 |

120 |

|

|

4TG-F179*5390 |

245 |

65 |

360 |

65 |

325 |

1655 |

Φ60 |

G1 |

6600-7200 |

800 |

47-52° |

70 |

120 |

|

|

4TG-F179*5780 |

245 |

65 |

360 |

65 |

325 |

1750 |

Φ60 |

G1 |

7200-8000 |

1000 |

47-52° |

70 |

135 |

|

|

6TG-F179*5780 |

245 |

65 |

360 |

65 |

325 |

1270 |

Φ60 |

G1 |

7200-8000 |

1000 |

47-52° |

49 |

120 |

|

|

2 0 2 |

4TG-F202*5390 |

280 |

65 |

360 |

65 |

325 |

1675 |

Φ65 |

G1 |

6600-7200 |

800 |

47-52° |

92 |

165 |

|

4TG-F202*5780 |

280 |

65 |

360 |

65 |

325 |

1770 |

Φ65 |

G1 |

7200-8000 |

1000 |

47-52° |

96 |

165 |

|

|

4TG-F202*6180 |

280 |

65 |

360 |

65 |

325 |

1870 |

Φ65 |

G1 |

8000-8500 |

1000 |

47-52° |

96 |

185 |

|

|

5TG-F202*7200 |

280 |

65 |

360 |

65 |

325 |

1770 |

Φ65 |

G1 |

8700-9500 |

1000 |

47-52° |

88 |

185 |

Note: The above product models are our company's regular product models. Customers are requested to choose regular products as much as possible, which can improve the delivery time and service quality.

Workshop with advanced equipment:

Exhibition:

Certificates: ISO9001, IATF 16949:2016, CE,etc.

FAQ:

Q1: How about your cylinders compared with HYVA cylinder ?

Our cylinders can replace HYVA cylinder well, with same technical details and mounting sizes

Q2: What's your cylinder's advantages ?

The cylinders are manufactured by advanced equipments and made under strictly quality control processing.

The steel is quenched and tempered 27SiMn steel and all raw materials are good quality from world famous companies.

Competitive price!

Q3: When your company be established ?

Our company be established in 2002, professional manufacturer of hydraulic cylinders more than 20 years.

We had passed IATF 16949:2016 Quality control system, ISO9001, CE,etc.

Q4: How about the delivery time ?

7-15 days approximately.

Q5: How about the cylinder's quality gurantee ?

One year.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001, IATF 16949:2016, SGS |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

How do telescopic cylinders contribute to efficient and controlled extension and retraction?

Telescopic cylinders play a crucial role in enabling efficient and controlled extension and retraction. Here's a detailed explanation:

Nested design:

The nested design of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for efficient extension and retraction. Each stage extends or retracts in a synchronized manner, contributing to smooth and controlled movement. The nested structure also enables compact storage when the cylinder is retracted, optimizing space utilization.

Hydraulic control system:

The hydraulic control system is a key component that enables efficient and controlled extension and retraction of telescopic cylinders. It utilizes hydraulic fluid and pressure to drive the cylinder's movement. By regulating the flow of hydraulic fluid to each stage, the extension and retraction speed can be precisely controlled. This hydraulic control system ensures synchronized movement of the stages and allows for gradual and controlled extension and retraction.

Valve and cylinder design:

Telescopic cylinders incorporate specific valve and cylinder designs to facilitate efficient and controlled extension and retraction. Flow control valves, such as flow restrictors or throttle valves, are often used to regulate the flow rate of hydraulic fluid to each stage. These valves help manage the speed of extension and retraction, preventing sudden or uncontrolled movements. The cylinder design, including the bore size and rod diameter, is carefully engineered to optimize the balance between extension/retraction speed and force output.

Pressure relief and damping:

To further enhance controlled extension and retraction, telescopic cylinders may incorporate pressure relief and damping mechanisms. Pressure relief valves help prevent over-pressurization of the hydraulic system, ensuring that the cylinder operates within safe limits. Damping devices, such as hydraulic cushions or shock absorbers, can be integrated to dampen the impact or vibrations during extension and retraction, promoting smoother and more controlled movement.

Load-specific adjustments:

Telescopic cylinders can be adjusted to accommodate different load requirements, contributing to efficient and controlled extension and retraction. By adding or removing stages or adjusting the hydraulic pressure, operators can adapt the cylinder's performance to match the specific load conditions. This customization ensures optimal extension and retraction characteristics for different applications and load capacities.

Overall, the nested design, hydraulic control system, valve and cylinder design, pressure relief mechanisms, and load-specific adjustments all work together to enable telescopic cylinders to contribute to efficient and controlled extension and retraction. These features ensure smooth operation, precise positioning, and safe handling of heavy loads in various industrial applications.

Consulting the manufacturer's documentation and guidelines is important for understanding the specific capabilities and limitations of telescopic cylinders in terms of extension and retraction.

How do telescopic cylinders contribute to precise reach and manipulation?

Telescopic cylinders play a crucial role in enabling precise reach and manipulation in various applications. Here's a detailed explanation:

Extended reach:

Telescopic cylinders allow for extended reach in equipment such as cranes, excavators, booms, and material handling machinery. The nested design of telescopic cylinders, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access objects or work areas that are located at a distance.

Precise positioning:

Telescopic cylinders provide precise positioning capabilities, allowing operators to manipulate objects with accuracy. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, enabling smooth and controlled movement. This precise control is essential in applications that require accurate placement or manipulation of objects, such as in construction, manufacturing, or material handling.

Load handling:

Telescopic cylinders contribute to precise load handling by providing the necessary force and control. The cylinders are designed to handle heavy loads and can exert the required power to lift, lower, or manipulate objects with precision. The hydraulic control system allows operators to adjust the speed and movement of the telescopic cylinder, ensuring safe and controlled load handling.

Adaptability:

Telescopic cylinders offer adaptability in reaching and manipulating objects in various environments. Their nested design allows for compact retraction, making them suitable for applications with limited space. The ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions.

Support for attachments:

Telescopic cylinders often support attachments or tools that enhance reach and manipulation capabilities. For example, in excavators, telescopic cylinders are used to extend the boom or arm, while additional attachments such as buckets or grabs facilitate precise material handling or excavation tasks.

Overall, telescopic cylinders contribute to precise reach and manipulation by offering extended reach, precise positioning, load handling capabilities, adaptability, and support for attachments. Their hydraulic control system and nested design enable operators to achieve accurate and controlled movements, enhancing productivity and efficiency in various applications.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the telescopic cylinder's capabilities, operating parameters, and recommended maintenance practices to ensure optimal performance and safety.

What industries commonly use telescopic cylinders in their applications?

Telescopic cylinders find applications in a wide range of industries where extended reach, height adjustment, or lifting capabilities are required. Here's a detailed explanation:

Industries commonly using telescopic cylinders:

- Construction: The construction industry extensively utilizes telescopic cylinders in various equipment, including excavators, backhoes, loaders, cranes, and concrete pumps. Telescopic cylinders enable the extension and retraction of booms, arms, or buckets, providing the necessary reach, digging, and lifting capabilities in construction and earthmoving applications.

- Material Handling and Logistics: Telescopic cylinders are essential in industries involved in material handling and logistics operations. This includes applications such as cranes, forklifts, loaders, conveyor systems, and automated storage and retrieval systems. Telescopic cylinders enable the lifting, tilting, or extending movements required for efficient loading, unloading, and transportation of materials.

- Agriculture: The agricultural sector employs telescopic cylinders in various machinery, such as tractors, harvesters, sprayers, and irrigation systems. Telescopic cylinders facilitate height adjustment, folding/unfolding of implements, and movement of equipment parts, enhancing productivity and efficiency in agricultural operations.

- Transportation and Automotive: Telescopic cylinders play a role in the transportation and automotive industries. They are used in applications such as dump trucks, trailers, refuse trucks, car haulers, and hydraulic ramps. Telescopic cylinders enable the efficient tilting, dumping, or lifting of cargo, enhancing the functionality and versatility of transportation equipment.

- Marine and Offshore: The marine and offshore industries utilize telescopic cylinders in applications such as ship cranes, offshore platforms, and subsea equipment. Telescopic cylinders enable the extension and retraction of booms, arms, or lifting mechanisms, supporting various marine operations including cargo handling, offshore construction, and underwater exploration.

- Mining and Quarrying: In mining and quarrying operations, telescopic cylinders are employed in equipment such as excavators, loaders, and conveyor systems. They facilitate the necessary extension and retraction movements for digging, lifting, and conveying materials, enhancing productivity and efficiency in mining operations.

- Utilities and Energy: The utilities and energy sectors utilize telescopic cylinders in applications such as utility trucks, aerial platforms, power line maintenance equipment, and renewable energy installations. Telescopic cylinders enable the safe and efficient access to elevated work areas, equipment maintenance, and positioning of components in energy infrastructure.

- Manufacturing and Industrial: Telescopic cylinders are found in manufacturing and industrial environments in various machinery, including automated systems, assembly lines, robotic arms, and material handling equipment. They provide the necessary linear motion and reach for precise positioning, lifting, or transferring of components during manufacturing processes.

These are just a few examples of industries that commonly use telescopic cylinders in their applications. The versatility and efficiency of telescopic cylinders make them valuable components in numerous sectors where extended stroke lengths or compact retracted lengths are required.

It's important to consult industry-specific guidelines and regulations to ensure the proper selection, installation, and maintenance of telescopic cylinders based on the specific application requirements.

editor by CX 2024-04-08