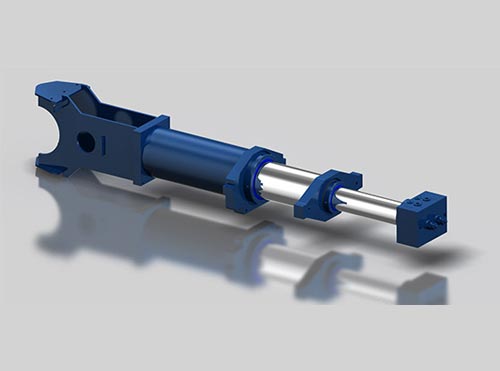

Product Description

1.Main Description

ETERNAL company design and manufacture heavy duty hydraulic cylinders that covering

the following fields:

Ø hydraulic press cylinder

Ø construction machinery cylinder

Ø mining machinery cylinder

Ø metallurgy machinery cylinder

Ø water power project cylinder

Ø marine hydraulic cylinder

Ø servo hydraulic cylinder

2. Design

Not only we could manufacture all kinds of hydraulic cylinders according to the drawing from our

customers,but also we could make a design according to customer's requirements.If you

require our engineer to make a design,pls advise us the following specification:

1. Rated pressure

2. Working pressure

3. Test pressure

4. Working condition and environment ,for example ,temperature ,working frequency

5. Pulling force ,and return stroke force

6. Pulling and return speed

7. Assembly size

8. Seal ring requirements .For example , brand ,seal material etc .

9. Tube and piston rod raw material requirements

10. Piston rod surface treatment requirements, for example chromating film thickness ,

Surface hardness etc .

11. Painting and other spare parts requirements .

3. Manufacturing capability and cylinder size range

3.1 Cylinder bore diameter :max Ø1200mm

3.2 Cylinder length :10Meter

3.3 Max lifting capability :50 Tons

4.Manufacturing and inspection

4.1.Cylinder tube size and choice

4.1.1 According to the cylinder pressure and inside diameter size ,different steel tube Would be choosed .

1. ID ≤300mm , cold rolled precision seamless tube would be choosed

2. 300mm≤ID ≤500mm , hot rolled seamless tube would be choosed

3. 500mm≤ID ≤1000mm, forged tube would be choosed

4.1.2 Cylinder tube steel grade : SAE1571 , SAE1045 ,27SiMn , S355JR ,S355J2G3

St52-3 ,SUS304 ,SUS316L etc .

4.1.3 Cylinder tube inside boring and honing , roughness R0.2-R0.3,

4.1.4 Cylinder tube inside chromating : if necessary ,tube inside chromating could be applied

.

4.2 Piston rod is a very important part for hydraulic cylinder .

4.2.1 Piston rod steel grade : SAE1045, 42CrMo4, SUS410 ,SUS420, SUS304, SUS316L

4.2.2 Piston rod chromating and surface hardness .

Eternal company ensure that every piece piston rod would be surface hardened before chromating ,

surface hardness is HRC55~60 , Chromating film thickness is 0.03~0.04mm if there is no other specific

requirements .

4.3 Seal ring and O ring

According to the customers' requirements and working condition , eternal company would choose suitable

seal ring kit , seal ring brand include :Parker , Merkel , NOK , HangZhou Rubber institute , ZheJiang brand etc . Eternal company would supply suitable seal solution for their customer so that hydraulic cylinder has more

lifetime , easy maintenance and simple repairing .

4.4 Tube and flange welding

The welding on cylinder tube and flange would be Ultrasonic tested every time , the welding seam would be

cleaned before machining .Eternal company ensure that every welding seam has no any leak during lifetime

4.5 Assembly and pressure test

Before hydraulic cylinder is assemblied , every spare parts would be measured and cleaned .After hydraulic

cylinder is assemblied , pressure test would be carried out one By one , eternal company ensure that testing

pressure is higher 30%-50% than working pressure , and pressure holding time 30~60 minutes is necessary . Every piece hydraulic cylinder must be tested completely without any leak .

4.6 Painting and storage .

After hydraulic cylinder pass through pressure test , painting is necessary .

Processing

HangZhou CHINAMFG Heavy Industry Co.Ltd was established in 2008.Our products mainly include hydraulic baling machine , scrap shearing machine ,and all kinds of heavy duty hydraulic cylinders etc.

We specialize on design and manufacture heavy duty hydraulic cylinders , scrap baler machine and shearing machine .Our hydraulic cylinders are widely used in different industry fields including:construction machinery,mining machinery, hydro~power project, offshore drilling platform, steel plant equipment , marine machinery,hydraulic lifting system etc. We have gained 10 patents for our hydraulic cylinders.

In 2008, our servo cylinders with cylinder bore 950mm for steel mill were exported to Poland.In 2009, our hydraulic cylinders with stroke 10 CHINAMFG were exported to Pakistan for water conservancy project. In 2016,cyliner with weight 90tons has been exported to Russian sucessfully .

Our hydraulic cylinder range: Bore:1000mm, Stroke:12 meter, testing pressure:50MPa We could make all kinds of hydraulic baler , hydraulic shear , scrap steel shredder machine , etc rated from 100 tons -1250tons . We could make all kinds of excavator spare parts , drill rig spare parts , steel mill spare parts according to OEM drawing , including all kinds of shaft and drill tools . We have heavy duty workshop with area 10000 square meters. There is doublelayer crane in the workshop.The lifting height could reach to 16 meter while lifting capacity could reach to 75 tons. Our machining equipment including Horizontal Lathe (11 meter ), Vertical CNC Machining Center, Display boring and milling machine, Frame type CNC machining center,CNC Lathe, Deep hole boring machine (13 meter), honing machine,etc. Testing equipment including Intelligent Pressure Test Machine, UT Detector, MT Detector, Chrome Thickness Meter, etc.

Eternal company would devote to supply first rate equipment and provide total solutionsto our customer. In the past 10 years, we devoted ourself to continuous market expanding and the researchand development of new products. Till now, our products have been export to nearly 50 countries and own good reputation from our customers .

You are welcome to visit our company !

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2008,sell to Domestic Market(36.00%),Eastern Europe(21.00%),Southeast Asia(16.00%),South America(12.00%),North America(9.00%),Northern Europe(4.00%),South Asia(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Hydraulic Cylinder,Hydraulic Baler,Hydraulic Shear,Drill Toll,Rollers

4. why should you buy from us not from other suppliers?

We have rich experience on hydraulic baling machine, scrap shearing machine and hydraulic cylinder ,our hydraulic press has passedh through CE certification .

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Western Union;

Language Spoken:English,Chinese,Portuguese,Russian /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE |

|---|---|

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Structure: | Piston Type |

| Material: | Alloy Steel |

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be repaired or maintained when necessary?

Yes, telescopic cylinders can be repaired and maintained when necessary. Here's a detailed explanation:

Repairability:

Telescopic cylinders are designed with repairability in mind. The modular construction of telescopic cylinders allows for individual components or stages to be replaced or repaired as needed. If a specific part of the cylinder becomes damaged or worn out, it can be disassembled and repaired or replaced, minimizing downtime and cost compared to replacing the entire cylinder.

Maintenance:

Maintenance is essential to ensure the optimal performance and longevity of telescopic cylinders. Regular maintenance practices may include:

- Inspection: Periodic visual inspections to check for any signs of damage, wear, or leakage.

- Lubrication: Applying lubricants to the moving parts of the cylinder to reduce friction and extend component life.

- Cleaning: Removing dirt, debris, and contaminants that may affect the cylinder's operation.

- Seal replacement: Replacing worn or damaged seals to maintain proper sealing and prevent fluid leakage.

- Pressure testing: Conducting pressure tests to ensure the cylinder's integrity and identify any potential issues.

- Alignment and adjustment: Verifying proper alignment and making necessary adjustments to ensure smooth operation and prevent excessive wear.

Depending on the specific application and operating conditions, maintenance intervals and procedures may vary. It's important to follow the manufacturer's maintenance recommendations and guidelines for the telescopic cylinder to ensure effective maintenance practices.

Professional expertise:

Repairing and maintaining telescopic cylinders often require professional expertise. It is recommended to engage qualified technicians or service personnel with experience in hydraulic systems and telescopic cylinder repairs. They have the knowledge and tools necessary to accurately diagnose issues, perform repairs, and conduct maintenance tasks in a safe and efficient manner.

Manufacturer support:

Manufacturers of telescopic cylinders typically provide support for repair and maintenance. They may offer technical documentation, repair manuals, and access to replacement parts to facilitate the repair process. Consulting the manufacturer's resources and seeking their assistance can ensure that repairs and maintenance are carried out correctly and in accordance with the cylinder's specifications.

By implementing proper repair and maintenance practices, telescopic cylinders can be kept in good working condition, extending their service life and maintaining reliable performance.

It's important to note that repair and maintenance should be performed by qualified individuals and comply with relevant safety guidelines and industry standards.

Can telescopic cylinders be used in agricultural machinery for various tasks?

Yes, telescopic cylinders are widely used in agricultural machinery for various tasks. Here's a detailed explanation:

Versatile applications:

Telescopic cylinders offer versatility and are suitable for a wide range of tasks in agricultural machinery. They are commonly employed in equipment such as tractors, harvesters, sprayers, loaders, and tillers.

Lifting and lowering:

Telescopic cylinders are utilized for lifting and lowering applications in agricultural machinery. They provide the necessary force to raise and lower attachments such as loader buckets, tillage implements, or harvest platforms. The telescopic cylinder's design allows for efficient force transmission, enabling smooth and controlled movement.

Reach extension:

Telescopic cylinders are valuable for extending the reach of agricultural machinery. For example, in a harvester, telescopic cylinders can extend the reach of the harvesting arm, allowing operators to access crops in a broader area. This extension capability increases efficiency and productivity by reducing the need for repositioning the machinery frequently.

Adjustable working height:

Telescopic cylinders are employed in agricultural machinery to provide adjustable working heights. For instance, in sprayers or spreaders, telescopic cylinders can adjust the height of the booms or spreading mechanisms, allowing for precise application of fertilizers, pesticides, or seeds.

Folding and unfolding:

Telescopic cylinders are used to facilitate folding and unfolding actions in agricultural machinery. This is particularly useful for equipment that needs to be transported or stored in compact configurations. For example, telescopic cylinders can fold the wings of a tillage implement for easy transport on roads or through narrow gateways.

Stabilization and leveling:

Telescopic cylinders contribute to the stabilization and leveling of agricultural machinery. They are employed in tasks such as adjusting the height and angle of plows, cultivators, or balers to ensure proper ground engagement and uniform performance.

Advantages of telescopic cylinders in agricultural machinery:

Telescopic cylinders offer several advantages in agricultural machinery:

- Versatility: Telescopic cylinders can be used for various tasks, providing flexibility and adaptability in agricultural operations.

- Efficient force transmission: The telescopic design allows for direct and efficient force transmission, maximizing the equipment's lifting and operational capabilities.

- Precise control: Telescopic cylinders enable precise control over movements, allowing for accurate positioning and improved productivity.

- Space optimization: Telescopic cylinders contribute to space optimization by enabling folding or compact configurations, facilitating transportation and storage of agricultural machinery.

Overall, telescopic cylinders are valuable components in agricultural machinery, offering versatility, efficient force transmission, precise control, and space optimization. They enhance the functionality and productivity of agricultural equipment across various tasks and applications.

It's important to consult the equipment manufacturer's documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in agricultural machinery.

How does a telescopic cylinder contribute to precise reach and positioning?

A telescopic cylinder plays a crucial role in achieving precise reach and positioning in various applications. Here's a detailed explanation:

Nested structure:

The nested structure of a telescopic cylinder, consisting of multiple stages or sleeves that retract inside one another, enables precise reach and positioning. Each stage can be extended or retracted individually, allowing for incremental adjustments in the cylinder's length. This modular design provides fine-tuning capabilities, enabling operators to achieve the desired reach and positioning with accuracy.

Controlled extension and retraction:

The hydraulic control system of a telescopic cylinder ensures controlled extension and retraction of the stages. By regulating the flow of hydraulic fluid to each stage, operators can precisely control the speed and movement of the cylinder. This control allows for smooth and gradual extension or retraction, facilitating precise reach and positioning without abrupt or jerky movements.

Adjustable stroke length:

Telescopic cylinders offer the advantage of adjustable stroke length. The hydraulic system can be adjusted to vary the extension and retraction distance, allowing for customization based on the specific reach and positioning requirements of the application. This adjustability enables operators to adapt the cylinder's stroke length to different tasks and working conditions, ensuring precise and optimized reach.

Position feedback systems:

In some applications, telescopic cylinders may be equipped with position feedback systems. These systems utilize sensors or transducers to provide real-time feedback on the cylinder's extension or retraction position. By monitoring the position, operators can precisely track and control the reach and positioning of the cylinder, enhancing accuracy and repeatability.

Stability and rigidity:

Telescopic cylinders are designed to maintain stability and rigidity during operation. The nested structure, along with the hydraulic system, helps minimize unwanted oscillations or vibrations that could affect reach and positioning accuracy. This stability ensures that the cylinder maintains its intended position without undesired movement or deflection.

Overall, a telescopic cylinder contributes to precise reach and positioning through its nested structure, controlled extension and retraction, adjustable stroke length, position feedback systems (if equipped), and stability. These features enable operators to achieve accurate and repeatable reach and positioning in various applications.

It's important to consult the manufacturer's guidelines and specifications, as well as follow proper maintenance practices, to ensure the reliable and precise performance of telescopic cylinders in achieving reach and positioning requirements.

editor by CX 2024-02-26